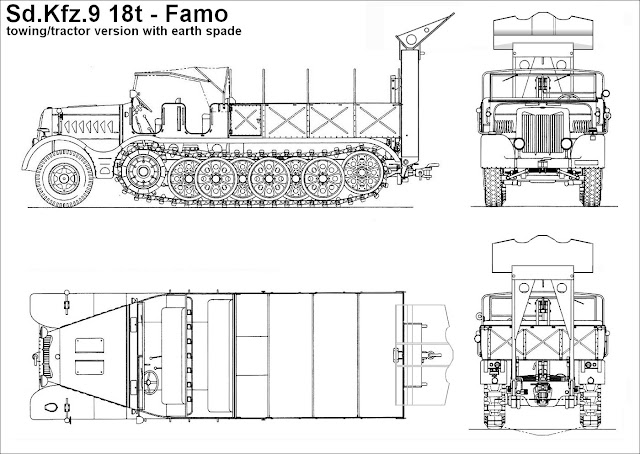

For this project I will use a wonderful kit, manufactured by Tamiya in 2000: the Schwerer Zugkraftwagen 18t "FAMO" und Tiefladeanhänger für P.Kpfw. Sd.Ah.116 (# 35246), in 1:35 scale.

Although it is a twenty-year-old kit, I can only classify it as fantastic, with the Tamiya standard of injection quality, detailing and ease of construction. And I will also use an accessory part also manufactured by the same Tamiya, the Tank Recovery Accessory Set for German 18 ton half-track (# 35243), which is nothing more than the earth spade for my Famo!

|

| Cabin and "engine room"... |

|

| ...under construction!! |

My girl will wear more traditional makeup (she's shy ...), in panzer-gray tones. Let's start painting the lower and more hidden parts (OMG ...) of it in gray, before proceeding ...

|

Panzer-gray in the chassis and suspension. Notice the engine

and transmission... |

|

| Adding details in metal (scratch) in the firewall of tractor |

|

| Again, the glorious panzer-gray |

|

The steel cable was made with twisted waxed wire for making bijoux necklaces

(red arrows) |

|

| The steel cable painted in matte-black...starting the weathering... |

|

| With weathering, the engine and transmission lose the "toy" aspect |

|

| Firewall with weathering and in gray tones... |

|

| The engine bay under construction... |

|

Notice the radiator "hoses" made with the insulation of electrical wires ...

The girl has a cold heart ... |

|

...and speaking of "hoses", let's give the air filter hose a more real look.

An "accordion look" made with scraps of enameled wire ... |

|

Final results... the air filter hose got much better,

after wire, matte-black and dry-brush... |

|

| Kojak loves a clean and organized engine bay ... |

|

| Notice the radiator aspect... |

|

I replaced the two plastic ties (very fragile ...) by two stainless steel ties.

One of the advantages of being dentist, in my spare time:

having great alternative materials on hand !! |

|

Closing the engine bay with upper hood.

I will not install the engine-bay sides ...

I want to expose certain details of my girl.

She has beautiful side-boobs !! |

|

| Right-side!! |

|

Now, it's time to build the easel for raising the sword.

For this, we will build the cargo area and make some adjustments .... |

|

The central guide of the steel cable, previously installed.

Do not forget that the spare will not be installed on the chassis in this version ... |

|

The biggest question is about the height of the easel.

For this, I installed the earth-spade for reference ... |

|

| Plastruct and patience ... and the easel is ready !!! |

|

I made two reinforcements at the base of the easel, on my own ...

Kojak is a thoughtful guy .... |

|

| The easel ready, with Chuck's approval !! |

|

The easel, after german-gray painting...

left side |

|

| Right side |

|

And the cargo-bay in position...

Before gluing the cargo area in position, I painted the bottom in panzer-gray ... |

|

| The tractor is almost ready!!! |

|

The easel, with earth-spade frame in position...

Notice the details added in the tractor |

|

| Right side... |

|

The earth-spade complete, in transit position...

Right side view |

|

The tractor is almost ready for the final details...

Now, I'll start the heavy trailer... |

Starting the trailer... Now, a big warning!! In the step 29, the beginning of the trailer, we're going to use some nuts and bolts (I love you, Tamiya!). And there are two types of nuts: some small and some slightly larger ... But the instructions, there is a small detail that can mislead you: the nuts that we will use in step 29 are described as SMALL NUTS. But the (correct) drawing and measurement (2mm) indicates that they are the biggest nuts ... and at the future steps, in step 52, the smaller nuts are described only NUTS, but the (correct) drawing and size (1,6mm) refers to the small nuts ... See below:

|

Step 29...Warning...Nut (small) are the big ones...

The smallers (step 52) are just called nuts...

But the drawings are correct!!! |

|

The front suspension of the trailer is under construction...

The plasticard stripes are from Tamiya's kit...perfect!! |

|

| Notice the nuts in position!!! |

|

| Front mainframe almost ready... |

|

Time to assemble the steering system of coupling device

Metal steering rods. Shorts...no doubt this time... |

|

The little Philips screwdriver comes with the kit ...

Tamiya rules!!! |

And the entire front suspension moves, according to the coupling device. Of course, this is not a toy, but it allows the placement of the trailer in a diorama, for example ... Besides being very cool !!!

|

| The steering device in action... Eyes front!!! |

|

| Eyes right!! |

|

| Eyes left!! |

I was almost forgetting to mention this important detail: before installing the metal clamps, check that the "eyes" are aligned with the clamp. It is very common for the end of the "eye" to be bent and if you install the clamp like this, the screw forces the clamp to the wrong position. The correct thing, if it is bent, is to use pliers and realign the discrepant tip. With this alignment, the eye is flat with the long axis of the clamp ... Look at the figures below:

|

Notice the eyes of the clamp: The top one is folded down ...

The bottom one was realigned with the pliers |

|

The perfectly aligned clamps ...

The small screw does not exert tension on the joint ... |

|

| The front trailer is ready... |

|

Time to do the same with the rear suspension....

Notice the big nuts in position, in the rear suspension... |

|

| The rear of the trailer is growing... |

|

Starting the steering system of the small cabin at the rear of the trailer...

Do not forget to check the alignment of the eyelets of the clamps,

as described in the first assembly, a little above ... |

|

| Rear suspensions of the trailer... |

Here I found out that I was drawn with the absence of one of the 1.6x10mm Philips type screws. The packaging was sealed, but someone forgot a screw ... Hell !!! Good thing I have a Dremel and a willingness to challenge: time to make a small metal pin ...

|

The mystery of the missing screw ...

But it's no use crying: let's make a metal pin to replace it ... |

|

The new pin in position!!!

The brake hubs have movement and resistance, now ... |

|

| Full assemble of the rear uspension... |

|

Testing the movment!!!

Eyes right!! |

|

| Eyes left!! |

|

The little rear cabin. Notice the big cable roll (red arrow)

and the retractable ladder.... |

|

The rear's cabin ladder movment...

So cute, so Tamiya!! |

|

| And speaking of cute !!! |

|

| Soooo kawaii!! |

|

| Kawaiii!!! |

|

| Cabin and wheels!!! |

|

| The front and rear trailer's suspension sets |

|

Starting the cargo bed...

Notice on the metal reinforcement stringers so that the model does not bend... |

|

The stringers are attached to the structure, like a sandwich,

but I reinforced everything with a superglue "welding" .... |

|

| The trailer's chassis... |

|

| ...under construction!! |

|

Do you remember the small nuts from step 29 ??

Here they are, almost at the end of the story ... |

|

| The rear ramps show movement ... |

|

| Uff ... the thing is almost done !!! |

As I said before, the Tamiya kit is complete, with many accessories and details. And the chains are part of these details, but the chain that comes with the kit is a little too big, in my opinion. It is in plastic and with some burrs in the links that would be a hell to be removed. Taking advantage of the fact that I didn't like the size of the chain, I replaced the plastic chain by a metallic one, from my box of trinkets. I think it was much better !!!

|

| Damn it, Jim ... I'm not an engineer, but it just got a lot better !!! |

|

| And the metal chains in position.... rear of the trailer... |

|

| ...and in the frontal portion. |

|

Dr. McCoy was extremely satisfied with the result of the transplant...

Next step: Painting!!! |

Damn, I lost the pictures of the trailer painting ... my old Canon is starting to play tricks on me ... I'm so sorry !!! But to make up for it, I'm going to toast you with the images of a fantastic apparatus for building LBL tracks: I imported this complicated device directly from NASA: check out the Panzerserra Link Aligner, made with popsicle sticks ...

|

| Panzerserra Link Aligner, made with popsicle sticks |

|

The Panzerserra Link Aligner in action...

You align the links in the slot of the incredible device and

then glue the shoe-pads over the joints ... Super-easy !! |

|

| 47 links late... |

|

The two tracks, each with 47 links...

Notice the spare portion of track that left over,

to be loaded into the cargo area !! |

|

The girl with "rear" shoes...left side

|

|

| The girl with "rear" shoes...right side |

|

| The girl with all shoes... Pretty!! |

|

| The girl with all shoes... Cute!! |

The markings are the original ones from Tamiya, with a few more addenda. Meet the Tractor Famo Sd.Kfz.9 18t number 3, providing services at the Luftwaffe, Herman Göring Workshop Battalion, Vehicle Maintenance Company, Germany - 1943.

The bogies of the Sd.Ah.116 heavy trailer. The decals on the fenders, in red and white, were cut to fit the size of the pieces. The small irregularities of the cuts were then painted with white and red acrylic paint. The decals served as templates for these delicate paintings ...

|

| Rear bogie of the trailer, with its small rear driver's cab. |

|

Rear bogie, rear view...

|

|

| Rear bogie, left view... |

|

Rear bogie, front view...

Meet Paula, the heavy trailer!!! |

|

| Front bogie, front right view... |

|

| Front bogie, front left view... |

|

Dashboard instruments painted by hand...

Where's the decal, Tamiya?? |

Continuing the project ... Weathering...

|

Wash and dry-brush (I'm old school!!)

Left side |

|

| Right side |

|

| Rear top view |

|

| Driver station |

|

| Right side of Sd.Ah.116 heavy trailer |

|

| Trailer's rear bogie |

|

| Trailer's front bogie |

|

Testing the composition...

A really big mothafocka !!! |

The colleague who ordered this project wants the vehicles with the tarps installed. I ordered the canvas from the crew area with

BoldDivision...But while this canvas does not arrive from Germany (the Post Office is always slow ...), we are making the tarpaulin from the cargo area in scratch ...

|

| BoldDivision crew stations canvas... |

... with the good and old technique of tracing paper. The first thing is to cut the tracing paper in the desired size. In this case, it will be enough to cover the cargo area, except for the last segment, because with the use of the earth spade and its erector device, the canvas should not reach there behind ... and also because with the folded canvas, the vehicle is more stylish ...

|

| the tracing paper already cut being tested in its position... |

A characteristic of tracing paper is to wrinkle all when moistened. We will use this feature to our advantage, simulating the normal folds of a canvas. It would look ridiculous if it were stretched like the leather of a drum ...

First, let's glue the first segment... We apply pure PVA glue with a fine brush to the marked areas and apply the tracing paper. With your fingers or using small sticks or spatulas, we wait for the paper to dry and adhere to the plastic. We can "mold" the paper in the meantime, taking advantage of the moisture of the PVA glue "soften" the paper ...

|

| Applying pure PVA glue with a brush ... |

|

We apply and keep the paper on the glued areas ...

Notice the paper "wrinkling" ... With the glue drying, it returns to normal,

but if we conform and shape the wet paper it in this step, it remains with "folds" .. . |

|

Extending the collage to the posterior segments ...

Let's do it in stages, to allow time to be able to

"model" the paper in position ... |

|

The first two segments glued to the first three frames ...

Now, it is time to wet these segments, to soften and deform the paper ... |

|

We apply a mixture of 60% PVA glue and 40% water to the glued segments

to wrinkle and reinforce the paper.

It is like the process of covering the old WWI fighters. |

|

With the paper softened, we can fold the paper much more easily ...

notice the rear fold of the canvas .... |

|

The paper drying spontaneously ...

Notice that it stretches, but not at all ... |

|

The canvas is fully finished, almost completely dry.

The final product is very convincing ... Right front view |

|

The canvas...right rear view...

|

|

And the canvas painted with Khaki and some tonal variations ...

Extremely satisfying, IMHO ...

Right view |

|

The canvas painted in Khaki and some tonal variations ...

Left view |

|

Cargo area in canvas, made with tracing paper... No bad!!

|

|

| Using the same colors for the rear bogie canvas ... |

|

And the Sd.Ah.116 heavy trailer is almost ready!!

|

Well, now is time to do the tie-downs in the canvas. The proposal is to make these details with simple materials and techniques, like the canvas itself. So, here we go: here's the basic concept drawing: tie it down with paper adhesive tape, cut out, painted and glued in position, with the help of small handles made with thin copper wire, folded with thin pliers. Let's see the photos ...

|

The tie-downs in concept...

|

|

| First of all, glued the paper tape on the cutting base, paint the tape... |

|

...and then cut with the scalpel.

Notice the pointed ends cut in the ribbons |

|

Parallel to this, we will make the metal "handles", which will be glued to the vehicle ...

I used thin cooper wire of dead coils from washing machines |

|

| Opening the holes for the handles, with drill ... |

|

Inserting the strips of paper tape under the canvas (red arrow) ...

Using the paper tape adhesive to keep the strip in place (straight blue arrow)

Then, folding the strip over the canvas (blue curved arrow)... |

|

| Almost all strips inserted and folded on canvas ... |

|

This step should be done individually, one strip at a time ...

Apply a superglue micro-drop just below an imaginary line between the two holes of the metal handles.

The strip will be folded and glued to this micro-drop ... |

|

Use a thicker piece of wire to allow for more perfect folding.

Be careful not to touch the glue with the wire ... |

|

Reviewing the metal parts of this step ...

In red, the metal for the strip's folds

In blue, the metal handles... |

|

After gluing the strip, remove the thicker wire and install

the thinner wire to make the handles.

Don't forget to apply MINIMUM amounts of superglue

to the vertical portions of the handles ...

Slide the handle into the holes, until the horizontal

portion of the handle rests on the strip ... |

|

| Don't forget to "bend" the tapered end of the strip ... |

|

A close-up image of the glue applied to the handle, before sliding ...

Apply the glue and slide, BEFORE the glue acts and keep

the handle in the wrong position ... |

|

| Applied handle and strips without handle ... Installation stages ... |

|

A tie-down in close-up vision...

|

|

All tie-downs in position...

left view |

|

All tie-downs in position...

right view

|

Good news: The BoldDivision stuff landed in my home:

|

Crew stations canvas and skirts for my Famo...

|

|

The box kit and the tractor girl...

|

|

The resin parts after cleaning...

Bad news: one of the canvas doors landed with a minor damage;

the absence of a part of canvas and the tie-down

of this sector... |

|

The side windows are huge, but I choose don't use...

The Famo's cabin it would be very "closed" ...

We are definitely not in winter !!! |

|

The missing portion... No problem: let's scratch!!!

|

|

| Making the tie-down with paper tape... |

|

Primmer (in white...)

|

|

And painted; notice the missing part!!!

Hurrah!! |

|

Some fuel drums for my old spare parts box...

Verlinden stuff..old, but good!!! |

|

Building a cargo for the cargo bay of Famo:

a rectangular piece of styrofoam with

tracing paper and pva glue...

|

|

Glued in place...

|

|

And with the drums...

rear left vision.. |

|

Right rear vision...

|

I decided to add a vehicle on the board of Sd.Ah.116. The chosen one was a Panzer II Ausf J. Something like this ...

The task is much easier, since I have such a beauty on my shelf. I built this light tank in 2012 in my Bunker

(see here...) and I'm going to take the opportunity to do some up-grades ...

The headlight lenses are strange and the red extinguisher is an old sin ... I'll fix these details now ... Notice the absence of the lens in the headlights and the fire extinguisher painted in khaky, as in the original vehicles. I took advantage and repainted some pieces of wood.

|

Panzer II Ausf J in the trailer

Notice the details in the tank's front |

|

I made a locking system with tree trunks (red arrows) , interconnected by moorings.

No chance of the tank slipping off the trailer ...

Notice the wood crate for tools, in the up track, in this side... |

|

Front part of the trailer with tank.

Notice the locking system with tree trunk, planks and jerry-cans and oil cans.

The tow bars are supported on the tank's front lashing eyes, ready for use ... |

|

Rear part of the trailer with tank.

notice the wooden trunk, the boxes and the mooring chains |

|

Rear view, right side...

|

|

The Panzer II Ausf J PUMMELIG ("Chubby") tied and locked in transport position ...

Kojak is really an efficient and responsible guy !!

Notice the rear cab windshield insulation with paper tape |

|

Tied and locked!!

|

|

The rear part of the Sd.Ah.116 trailer...

Details and accessories...

Notice the insulation of the rear cabin windshield

with paper-tape for the dust painting step... |

|

...just like the Famo!!!

|

And the project was ready: Meet the SdKfz 9 Famo 18t number 3 with Sd.Ah.116 heavy trailer PAULA, providing services at the Luftwaffe, Herman Göring Workshop Battalion, Vehicle Maintenance Company, in the rear front in Germany. The composition is supporting the transportation of a Panzer II Ausf J PUMMELIG from the 12th Panzerdivision (Heer), serving in "Kompanie Bethke", in the Eastern front, after an overhaul in Germany in 1943. First, the Famo tractor:

|

SdKfz 9 Famo 18t number 3 - Luftwaffe - Herman Göring Workshop Battalion

Vehicle Maintenance Company, in the rear front in Germany- 1943 |

|

| SdKfz 9 Famo 18t - left side |

|

| SdKfz 9 Famo 18t - rear left view |

|

| SdKfz 9 Famo 18t with earth spade in position... |

|

SdKfz 9 Famo 18t with earth spade in position.

Right rear view |

|

SdKfz 9 Famo 18t with earth spade in position.

Right view |

|

| SdKfz 9 Famo 18t with Kojak and Rover, the dog!! |

|

Sd.Ah.116 heavy trailer PAULA with Panzer II Ausf J PUMMELIG

12th Panzerdivision (Heer) - "Kompanie Bethke", Eastern front,

after an overhaul in Germany in 1943 |

|

| Sd.Ah.116 heavy trailer PAULA with Panzer II Ausf J PUMMELIG |

|

Sd.Ah.116 heavy trailer - rear view

|

|

| Sd.Ah.116 heavy trailer - rear right view |

|

Kojak's locking system. Fast, simple and efficient ...

rear view |

|

Kojak's locking system. Fast, simple and efficient ...

front view |

|

| Everything in its place ... |

|

| Kojak personally taking care of transport security ... |

|

SdKfz 9 Famo 18t number 3 with Sd.Ah.116 heavy trailer PAULA,

providing services at the Luftwaffe, Herman Göring Workshop Battalion,

Vehicle Maintenance Company, in the rear front in Germany.

The composition is supporting the transportation of

Panzer II Ausf J PUMMELIG from the 12th Panzerdivision (Heer),

serving in "Kompanie Bethke", in the Eastern front, after an overhaul.

Germany in 1943. |

|

The full composition - front view

|

|

Famo and trailer, side by side.

|

|

Indeed...Kojak is a true handy-man!!

|

See you soon, Kameraden!!!

Skąd wziasc plastikowe paski do owiniec zbiornika z powietrzem??

ResponderExcluirGood morning!! More than 300, my friend...

ExcluirI congratulate what a beautiful model, a masterpiece, it's really fun to see what a brilliant work, my greatest respect, really fantastic result.🫡🫡🫡🫡🫡🫡🫡🫡🫡

ResponderExcluirThanks a lot, my friend!!! Hugs and all the best!!!

Excluir