Soldiers!!

Let's meet a brave and strong girl, who was facing the worst working conditions to allow the fight to develop in more favorable environments. We are talking about the Caterpillar D7 LaPlant-Choate R71 Trailbuilder dozer, used by several allied countries during WWII and after.

|

| Caterpillar D7 with LaPlant-Choate R71 Trailbuilder dozer France, August, 1944. |

The Caterpillar D7 is a medium bulldozer manufactured by Caterpillar Inc.. The first D7 appeared in 1938. The D7 dozer was the primary earthmover for construction of survivability positions and antitank ditches. It had to be transported by trailer due to its poor mobility.

|

| A veteran Caterpillar D7 still in use... Indeed, a tough girl !! |

During WW II crawler tractor / bulldozers were used by Allied military for combat construction in Europe, Asia, in the Pacific, literally all over the world. They also served as prime movers for artillery, and for a multitude of other tasks.

The crawler tractors had unsurpassed capability to move and tow in the muddy jungles of the Pacific islands which made them especially prized by the Americans SeaBees, Marine Corps and Army units in the Pacific Theater.

When equipped with a bulldozer blade, they could level ground for roads and airfields as well as clear debris, construct fortifications and much more.

|

| Heavy Tractor, M1 Caterpillar D7 818th Engineer Aviation Battalion in France - 1944 |

|

| Finnish D7 in Winter War. Notice the modified blade Thanks for the pic, Mikko Heikkinen!! |

|

| A Caterpillar D7 dozer gives an LCM(3) a helping hand. |

|

| Caterpillar in Guam, 1945 |

|

| Caterpillar D7 armoured cleaning the road. The King Tiger is not too heavy task for this girl!! |

|

| Caterpillar D7 with LaPlant-Choate R71 Trailbuilder (hydraulic) dozer in Gibraltar building an airfield with a steamroller |

|

| Seabee Caterpillar working in airfield at Admiralty Islands |

|

| Caterpillar D7 with LaPlant-Choate R71 Trailbuilder (hydraulic) dozer under maintenance.. |

Caterpillar D7 described:

The D7 was a big machine 4.114 mm long and 2.539 mm wide without any attachments), but it was also a phenomenal worker_ Fitted with Cat's own model D-8800, 4 cylinder, 80 horsepower, 13.617 cc liquid cooled diesel engine, it had a maximum drawbar pull over 11.500 kg.

With five speeds forward, four in reverse, it could work equally well in either direction. They can be fitted with a LeTourneau-type angledozer on which the blade could be manually adjusted to cut right or left, or to doze straight ahead. The power control unit can be front mounted, but. still relied on cables to raise the blade, A Hyster D7N 15 tons winch can be mounted at the rear, Weighing 14.400 kg, the D7 could tow loads exceeding 11.500 kg.

Caterpillar D7 Bulldozer variants (WWII era):

- D7 7M series, manufactured 1940-1944, approx 10,000 produced. D8800 engine, 74 inch track gauge (1.880mm)

- D7A 1T1001 series, manufactured 1943, 138 produced. Armor plated 7M with twin hydraulic cylinders, rear mounted Hyster D7N winch

- D7 3T series, manufactured 1944-1955, over 28,000 produced

- D7 4T series, manufactured 1944-1945

- D7 6T series, manufactured 1945

During WW II, the D7 was one of the bulldozers collectively known as "Tractor, Heavy, M1." Equivalent tractors were produced during WW II by Allis-Chalmers Co. (Model HD10W, G-98) and International Harvester Co. (Model TD18, G-101). About one thousand Caterpillar D7s were also produced by American Car & Foundry under license when WW II military orders exceeded Caterpillar's capacity.

See the movie below: a Caterpillar D7 in action:

Main Auxiliary Equipment:

- Hyster D7N Towing Winch: It was a robust, single-speed, direct-gear, reversible winch with enough power and strength to utilize the tractor's engine power to pull loads beyond those that could be handled on the tractor's drawbar. The winch must be operated with the tractor stationary.

|

| Hyster 07N towing winch installed in the rear of a Caterpillar D7 |

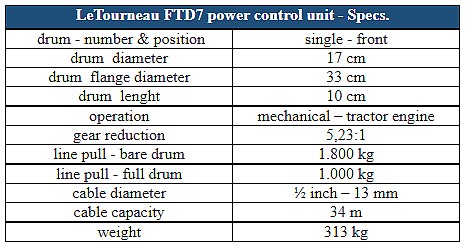

- LeTourneau FTD7 Power Control Unit: the FTD7 power control unit (PCU) was a single-drum unit mounted in the front of main frame of Caterpillar D7 tractors, below the radiator, for controlling a dozer blade used with the crawler. Could be used in conjunction with a rear mounted cable control unit or a towing winch . This front PCU was driven by the tractor engine. The cable drum of the PCU was connected with the dozer blade up over the sheave of A-frame and down to the dozer blade. By spooling or unspooling the cable on or off the cable drum , the PCU could controls the raising or lowering of the dozer blade. The operator operates the aparatus moving the control lever at the right of the tractor seat.

|

| LeTourneau FTD7 power control unit installed in front position of Caterpillar D7 tractor see also the cable arrangement and control lever |

- LeTourneau R7 Power Control Unit: the R7 Power Control Unit (PCU) was a double-drum unit mounted on the rear of the steering-clutch case of Caterpillar D7 tractors to control a wide range of equipment like dozers, scrapers, rooters, cranes etc. A take-off shaft (spline-shaft) connects the PCU with the tractor upper transmission-shaft, and by the tractor engine. Control cables (wire ropes) extend from the cable drums to the equipment that is being operated by the PCU. Two control levers (one for each drum) extend up behind the tractor seat and are within easy reach for the operator. Moving these control levers, the operater can spool or unspool the control cables on or off the cable drums, thereby operating the various working parts of the equipment being operated by the PCU.

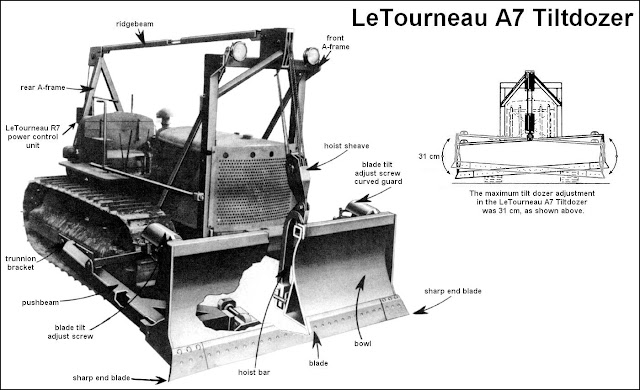

- LeTourneau A7 Tiltdozer: the A7 Tiltdozer consisted mainly of the steel blade or "bowl" across the front of the tractor; the pushbeams, that supported the bowl in front of the tractor; the trunnion brackets, on which the rear of the pushbeams pivots; and the front and rear A-frames and the ridgebeam on which rotated the sheaves over which the cable from the PCU travels to raise and lower the blade. The A7 Tiltdozer could be operated by either LeTourneau front or rear mounted PCUs. The bulldozer required only one cable drum, and when it is operated by a rear-mounted R7 PCU, the spare drum may be used to operate other equipment. By engaging the clutch of the power control unit, the blade will be raised. By releasing the brake, the blade will be lowered. Its design combined features of the bulldozer and the angledozer. The Tiltdozer blade can easily be tilted. The adjustment was performed by the blade tilt adjusting-screws, at the front of each tilting brace. The adjusting mechanism was protected by a curved guard. The sharp pointed end blades are a distinctive feature of the A7 Tiltdozers blades. The A7 Tiltdozer was introduced in 1943 but it is possible that the U.S.Army did not receive any before 1944.

|

| Cutaway view of LeTourneau A7 Tiltdozer controlled by LeTourneau R7 PCU in a Caterpillar D7 tractor. Notice the pointed sharp ends blade, typical of this blade. |

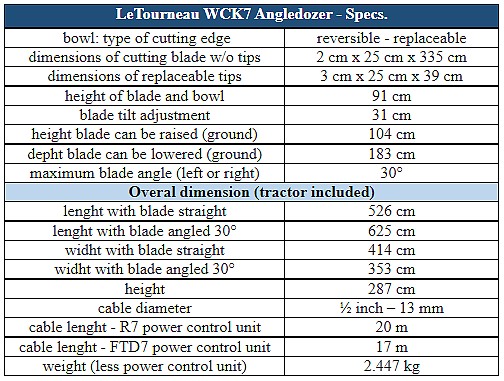

- LeTourneau WCK7 Angledozer: The LeTourneau WCK7 angledozer was composed of the steel blade or "bowl" across the front of the tractor; the yokes and sidearms, which supported the blade in front of the tractor; the trunnion brackets, on which the rear of the yoke pivots; and the front and rear A-frames and the ridgebeam which supported the sheaves over which the cable from the power control unit passed through to raise and lower the bowl. By operating the PCU control-lever, the dozer blade was raised and lowered as the tractor moves forward. The angledozer bowl could be adjusted into the angled position and into the tilted position. The WCK7 angledozer required only one cable drum, and when the tractor was equipped with a R7 PCU, the spare drum may be used to operate other equipment. The WCK7 angledozer was introduced in 1942 and it became the standard LeTourneau angledozer type for the military D7.

|

| LeTourneau WCK7 Angledozer Notice the possibilities of horizontal and vertical angulation of the dozer |

- LeTourneau XD7 Bulldozer: The LeTourneau XD7 Bulldozer consists mainly of the steel blade or "bowl" across the front of the tractor; the pushbeams, which support the bowl in front of the tractor; the trunnion brackets , on which the rear of the pushbeams pivots; and the front and rear A-frames and the ridgebeam which support the sheaves over which the cable from the PCU travels to raise and lower the blade. Engaging the clutch of the power control unit will raise the blade, returning the control lever to the neutral position will hold the blade in the raised position, and releasing the brake will lower the blade. The XD7 Bulldozer can be operated by either LeTourneau front or rear-mounted PCUs. The bulldozer requires only one cable drum, and when operated by a rear-mounted R7 PCU, the spare drum may be used to operate other equipmen. The XD7 Bulldozer was introduced in 1940. Its knock-down construction with detachable blade and pushbeams made it superior to a standard bulldozer like the WEK7 Bulldozer with its rigid bowl as it permitted easy disassembly for compact stowage or transportation, which is always good for logistics.

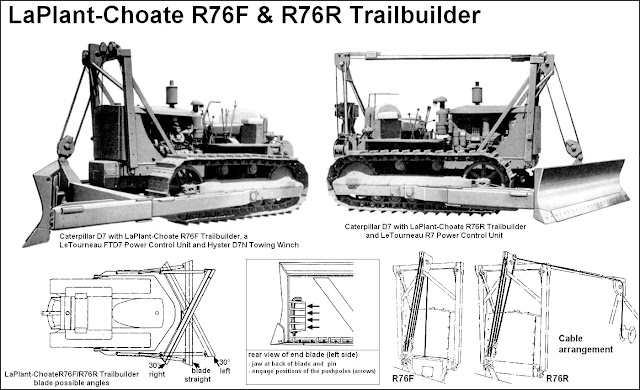

- LaPlant-Choate R76F and R76R Trailbuilder: the R76F (front) and R76R (rear) trailbuilders consists mainly of the steel blade across the front of the tractor; the pushpoles and the main frame, which support the blade in front of the tractor; the tractor mountings , on which the rear ends of the main frame pivot; the front overhead group, the overhead beam and the rear overhead-brace assembly which support the sheaves over which the cable from the PCU travels to raise and lower the blade. The R76F or R76R trailbuilder was a cable-operated angledozer that can be operated by any type of front or rear-mounted PCU. The standard combinations for Caterpillar D7 tractors in service with the U.S. Armed Forces normally were: LaPlant-Choate R76F Trailbuilder with LeTourneau FTD7 front-mounted PCU and R76R Trailbuilder with LeTourneau R7 rear-mounted PCU. The blade of the Trailbuilder may be angled 30° right or left or used as a straight bulldozer. The blade may also be tilted up or down at either end by removing the front pushpole pins and changing the position of the pushpole in the jaws blade locks.

|

| LaPlant-Choate R76F and R76R Trailbuilder Notice the possibilitie of horizontal angulation of the dozer (left below) and vertical tilt (center below) |

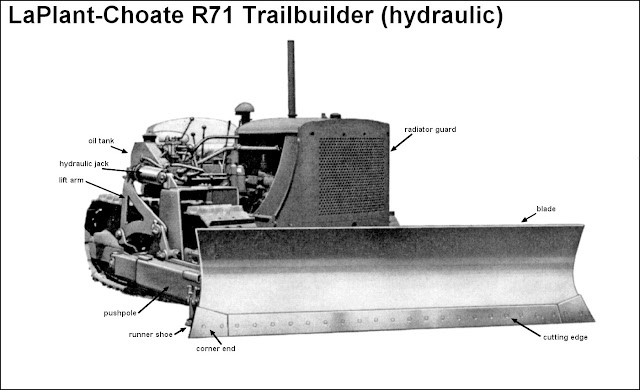

- LaPlant-Choate R71 Trailbuilder (hydraulic): the R71 trailbuilder was a hydraulic-operated angledozer, designed for the same operations as the cable-operated R76F and R76R trailbuilders. The R71 trailbuilder consists mainly of the steel blade across the front of the tractor; the main frame and pushpoles with runner shoes which support the blade in front of the tractor; the tractor mountings, on which the rear ends of the main frame pivot; the hydraulic system which includes a hydraulic pump, control valve, piping, oil reservoir and two hydraulic jacks. The hydraulic pump is bracked-mounted to the fan-belt pulley of the tractor engine and provides the hydraulic power to operate the jacks of the trailbuilder to raise and lower the blade. The trailbuilder is attached to the outside of the track frames on pivot-type mountings, and is lifted and lowered by means of two jacks. The jacks are double-acting, which allows down-pressure to be applied to the blade, as well as lifting-power. The blade may be used in the straight or bulldozing position, or angled 30° or right or left-hand delivery. The blade may also be tilted the same way as with the R76F and R76R trailbuilders.

|

| Caterpillar D7 equipped with LaPlant-Choate R71 Trailbuilder (hydraulic) with blade angled 30° to the right. |

Glossary:

- Bulldozers: (fixed blade) are used for moving rock , uprooting trees and stumps, leveling land, grading and maintaining roadways, digging holes and filling, stripping. A bulldozer blade was initially operated (or pushed) by a team of mules or horses. Early bulldozer blades, mounted on tracklaying tractors, were controlled by the operator by means of hand wheels. In the mid- to late 1920s, a hydraulic-controlled bulldozer blade was invented by LaPlant-Choate, and R. G. LeTourneau introduced a cable-controlled bulldozer, operated through a front- or rear mounted power control unit. With the time, the name bulldozer became associated with the complete bulldozer-equipped tractor, and not any longer with the attachment alone.

- Angledozers: (blades capable of being angled and tilted) are used for clearing, stripping, leveling, side-hill sloping, ditching, carving out roadways, building levees , and for airfield construction.

- Power control unit: used to operate other mounted equipment like bulldozers or angledozers and towed equipment like scrapers, graders or rooters.

- Pipelayers: are side-mounted cranes powered by the tractor, and will lift, lower, carry or bend pipes in pipeline construction. They are also useful in handling and placing poles and piles, setting machinery and in heavy loadlifting.

- Anglefillers: used for trench filling in combination with pipelayers, and eliminate the use of a separate backfiller or bulldozer.

- Winches: designed for towing purposes and for moving heavy loads that are too heavy to be properly handled with the tractor 's drawbar. They are also very useful in recovering disabled or stuck vehicles

Specs:

| Caterpillar D7 bulldozer M1 LaPlant-Choate R71 Trailbuilder (hydraulic) | |

|---|---|

| Type |

Crawler heavy tractor M1

|

| Place of origin |

United States

|

| Service history | |

| In service |

1911-1945

|

| Used by |

Allies

|

| Wars | WWII, Korea, Vietnan |

| Production history | |

| Designer | Caterpillar Inc. |

| Designed | 1938 |

| Manufacturer | Caterpillar Inc.- American Car & Foundry |

| Produced | 1938 - |

| Number built | + 39.000 |

| Variants | see text |

| Specifications | |

| Weight | 14.400 Kg |

| Length Widht Height | 527 cm 370 cm 2.40m |

| Crew | 1 |

| Engine Transmission |

Cat D8800 Diesel, 60/90 HP 4 cyl. 13.617 cc.

5 gears fwd. x 4 rev.

|

| Speed forw. | 18 Km/h |

| Speed rev. | 11,2 Km/h |

| Fuel tank | 247 liters |

| Fuel consum. Traction cap. Eletrical sys. | 22 liters/ hour 11.500 kg. 6 Volts |

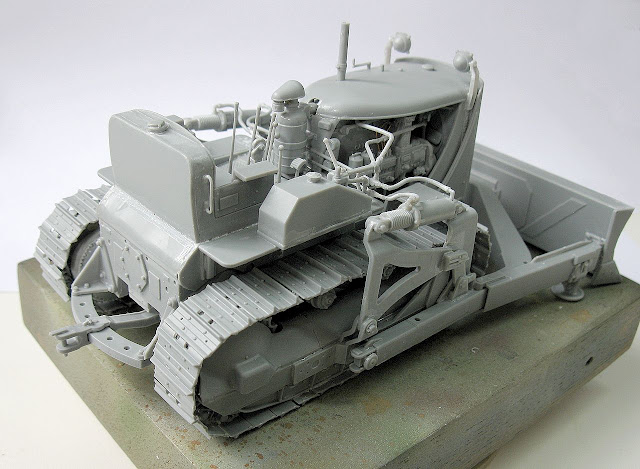

The kit:

Thank the Gods, today we are very well served in terms of tractors. Two Companies (MiniArt and Mirror) inject in plastic various versions of these vehicles, with very reasonable prices, in 1/35 scale:

As a matter of choice of version, I chose this young lady: Caterpillar D7 Bulldozer - Hydraulic blade version.

Let's start...

|

| In my workbench... |

|

| Tools, booklet and parts... |

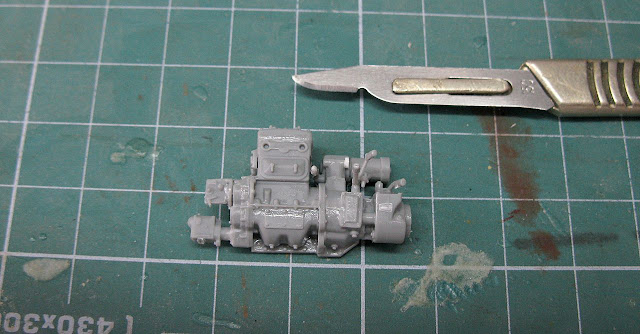

Well...Starting at the beginning: by the booklet !! Many parts are very, very small and fragile. but, the worst, impossible to be cleaned without damaging them. The Department of Engineering of MiniArt could have put the injection connections in more favorable cleaning places.

|

| Notice the size of parts and the position of connections |

Another criticism: parts that could perfectly be merged into larger pieces without diminishing the detail. Small pieces that add up to nothing in detail, but tired of building and cleaning. In summary, an annoying task, IMHO.

|

| The injection tips glued without cleaning. I'll do that in position Notice the part pinted by lower arrow: Why not casting in the engine block?? |

After the injection tips glued, I was able to clean them ...I used glue-welder to smooth the surface of the spark plugs...

|

| Injection tips cleaned, at last... |

And suffering (useless, in my opinion ...) continues. The piece that was in this position simply disappeared when cut. A lubrication plug that could have been cast in the big part WITHOUT ANY DETAILS LOST !!!

|

| Part made in styrene to substitute the missing plug!! Over-engineering, in my opinion. That doesn't make the kit better, just tiring... |

Another oil plug. Why this part was made in separate?? Why?? They look the infamous old Dragons 3x1 kits that had thousands of little (useless and invisible...) pieces and not sold in stores.

|

| Notice the size and BIG DETAIL of this oil plug... |

|

| And glued in place... Why?? Why? |

After 2 hours of pain, I build this:

Well,...After this outburst, we will continue the engine construction. I admit that is very detailed, but at least about 10 or 20 of these parts could simply be casted in the engine block, without problems. Again, IMHO!

|

| The metal part is there to replace a small parts that flies off and was not found ... Carpet monster strike back!! |

|

| More sub-assembles... |

|

| Well...the engine is almost there... |

It's definitely not a kit for beginners. The fragile parts and brittle plastic lead you to the madness. It's unpleasant to write that, but this kit did not provide to me pleasure, so far ... To me modeling is a nice hobby and not an irritation and suffering exercise.

But let's go ahead... the saga continues....

|

| The engine in the chassis... |

|

| Other side... |

Another piece with injection marks in its most fragile portion. The best option is to replace the portion with Plastruct:

|

| Impossible clean the injection marks inthis part... |

Control levers and cables. A pity that this detailing will disappear beneath the cabin floor...

|

| Details...amazing details...but... |

|

| ...Plastic is extremely brittle and fragile!! |

|

| All details disappearing ... Frustrating !! |

|

| The sponson of suspensions: sub-assemblie in position |

|

| The sponsons of suspensions: sub-assemblies in position |

And now, the nightmare: LBL tracks. I hate LBL tracks !!! And the worst is: the kit supplies the exact amount of parts. NO SPARE PARTS!!! If you break or lose a little bit, you are screwed!!!!!

|

| First of all, removing the small pieces from the trees ... |

|

| Cleaning the little parts!!! DO NOT BREAK OR LOSE none of these little pieces !!! |

|

| Beware!!! There are parts left and right for each link... Do not mix !! |

To build the tracks, forget the instruction manual !! I followed this method: I glued the pins in the half-segments of each link and then I inserted and glued the other half-segment, building the track, but without the pads.

|

| Pins glued in the half-segments... |

|

| ...and the other half-segment glued in the tip of the pin. |

|

| The tracks in position. Still moveable... |

|

| The two sets buit. |

|

| The tracks done: Total time spent with this step: 4 hours!! |

After the track's nightmare, the next building is a piece of cake!!

|

| Hydraulic pistons of blade |

|

| The tractor's body almost complete !!! |

|

| Right view |

|

| Suspensions in position. I usually paint the whole set ... Blade under construction... |

And, finally, the final assemble; blade in position. You can keep the set mobile, but I do not like it. I fixed the blade in the linear working position.

Next step: painting!!!

|

| The girl is big!!! |

|

| Olive-drab !! |

|

| ...and Future, to prevent silvering... |

|

| Decals... |

|

| The Allied star in the radiator shield was painted with stencil |

|

| Starting details... |

Final details:

|

| Headlights with bijoux details... |

|

| PVA glue in the interior of headlights... |

|

| New reflectors... |

|

| The original lense in the left headlight.. The right one in process... |

|

| Done!! |

And the new Canadian Girl was ready. Caterpillar D7 LaPlant-Choate R71 Trailbuilder dozer in duties with Royal Engineers Battalion, 2nd Canadian Corps, working in Falaise, France. August, 1944.

|

| Caterpillar D7 LaPlant-Choate R71 Trailbuilder dozer Royal Engineers Battalion, 2nd Canadian Corps Falaise, France. August, 1944. |

|

| Caterpillar D7 Bulldozer - left side |

|

| Caterpillar D7 Bulldozer - right side |

|

| Caterpillar D7 Bulldozer with Kojak and Rover, the dog. |

|

| M10 Wolverine GMC and Caterpillar D7 Bulldozer in size comparison |

|

| Caterpillar D7 LaPlant-Choate R71 Trailbuilder dozer Royal Engineers Battalion, 2nd Canadian Corps Falaise, France. August, 1944. |

As final thoughts, the kit is over-engineering, in my opinion. That doesn't really make the kit any better, just very, very tiring... The final product is very beautiful, but the same result could have been achieved with an infinitely better "assembly cost". Definitely not a starter kit. Fantastic, but extremely laborious in parts that didn't exactly need to be...

Thanks for following, Gents !!