Gunnies!!!

The

Diamond T Model 968A cargo truck - 4 ton - 6x6 (G509) were originally developed and produced during World War II.

The production beginning in 1941.at the behest of the Quartermaster Corps to serve as a prime mover for the 155mm howitzer. However, due to the success of these trucks, they were soon adapted to other roles as well.

|

| Diamond T Model 968A cargo truck - 4 ton - 6x6 (G509) |

History (truck):

The Diamond T was an American automobile manufactured in Chicago from 1905 until 1911 by the Diamond T Motor Car Company. It was a powerful touring car (models up to 70 hp were available). The company later became known for its trucks. By 1967, as a subsidiary of

White Motor Company, it was merged with

Reo Motor Company to become

Diamond Reo Trucks, Inc.

During World War II, Diamond T produced a classic heavy truck in the

980/981, a prime mover which was quickly acquired by the

British Purchasing Commission for duty as a tank transporter tractor.

|

Diamond T 980 tank transporter with a Churchill tank

during preparations for crossing the Rhine. |

Coupled with a Rogers trailer, the truck gave sterling service with the British Army in

North Africa Campaign, where its power and rugged construction allowed the rescue of damaged tanks in the most demanding of conditions.

|

British Diamond T 980 recovering

a Grant in the desert |

Early production of these trucks were all built in the closed-cab version of the Diamond T chassis. While the hood and fenders were strictly military, the cab itself was based on Diamond Ts commercial truck cabs.

|

| Diamond T 968A closed cab |

The designation was changed to Model 968A when military standard instruments and components were substituted. It was produced with both the closed metal cab and, by 1943, open soft-top military cab, which allowed greater visibility and better air defense. The final version was 968B

In addition Diamond T built the entire range of the G509 series 4 ton 6X6s, including cargo, dump, semi tractor, and wrecker trucks.

The 4 ton 6x6 truck:

The Diamond-T 968 Truck, Cargo, 4 ton, 6x6 was powered by the Hercules RXC 529-cid inline six-cylinder petrol engine. The high-torque engine and low gearing of the five-speed transmission and two-speed transfer case allowed a highway towed load rating of 12 1/2 tons. The truck weighed 8.400 Kgs and could tow 11.500 Kgs. The Diamond-T Model 969 Wrecker was built on the same G-509 chassis.

967, 968, 968A & 968B Cargo Trucks

These trucks were referred to as short wheelbase trucks and were intended to transport personnel. general cargo, or to act as a prime mover for 155mm Howitzers.

|

| Diamond T 968A towing a 155mm howitzer in Boungaville. 1944. |

|

| Diamond T 968B towing a 155mm howitzer after D-Day. |

Like almost all the WWII cargo trucks, the beds of these trucks initially were made of steel, but were changed to wood construction early on. The two spare tires were carried across the front of the bed. The Model 967, produced in early 1941. was first in the Diamond T series and was powered by the Hercules RXB 501-cid inline six-cylinder engine. The 967 is easily distinguished by its one-piece brush guard, which extends to protect the headlamp.

|

| Diamond T 967 - notice the one-piece brush guard |

Later models have a narrower brush guard. with separate guards for the headlights. The Model 968. introduced later in 1941. was upgraded to the larger. more powerful Hercules RXC engine. The Model 968A. which began production in November 1941. featured the military-type instruments instead of the civilian style used previously.

|

Diamond T 968A - Notice the narrower brush guard.

with separate guards for the headlights. |

|

Diamond T 968A with .50 ring

and wood truck bed (1943) |

The Model 968B was the final version of the short wheelbase 4-ton Diamond T.

|

| Diamond T 968B |

969, 969A, & 969B Wreckers

While 21 wreckers were built on the 967 chassis in 1941. the most well-known Diamond T wrecker was a variant of model 969. The designation was changed to 969A when the instruments and filters were changed to the Military Standard type. The 969B was built for foreign aid requirements. and is most easily spotted by its single headlight and single taillight, along with different paint.

All model 969 trucks were built with closed cabs, while the 969A and 969B were built in both open-and closed-cab forms.These trucks were built with a Bendix-Westinghouse air brake system. and a dual 6- and 12-volt electrical system. The Diamond T wreckers were equipped with the Holmes W-45 H.D. military wrecker bed. This bed was an adaptation of the standard Holmes W-45 twin-boom civilian wrecker. The first of the 6,420 G-509 wreckers to arrive was the model 969 was built in February of 1941. The first unit carried serial number AB 1-101. The "A" in the first position of the serial number identifies the bed as a military W45 H.D. model.

|

| Diamond T 969A wrecker with M36 ring for .50 MG |

The Holmes W-45 wrecker is a twin-boom design with two 5-ton winches mounted behind the cab. Each winch is equipped with 60 m. of wire rope. The twin-boom design allows side recoveries to be made by swinging one boom to that side, and swinging and tying off the other boom to the opposite side to stabilize the wrecker. There are also stabilizer legs mounted on each side of the bed, just behind the cab. Typical of U.S. military wreckers, these trucks carried a lengthy list of recovery equipment. including chains, ropes, snatch blocks, cutting torches, and tools. Unlike the later M series wreckers, which used the truck air brake system as an air source for tire inflation etc, the W-45 left the factory with a self-contained air compressor mounted between the booms. However, the compressor is often missing, even in many wartime photos of these trucks. In addition to the winches on the Holmes bed, the trucks were also equipped with a 7.500 kgs.-capacity Gar Wood winch mounted behind the front bumper.

970 & 970A Pontoon trucks and 975.

While these trucks look very much like the 967 and 968 series trucks, they are slightly longer. The bed is 406mm longer and the wheelbase is 4368mm (172") The spare tires were carried between the back of the cab and the bed. The Diamonds T long wheelbase was designed to transport pontoons for temporary bridging for US Army. The spare tires were carried back of the cab. in the side of the bed.

|

| Diamond T 970 Pontoon truck |

The Diamond 975 had a cab/chassis configuration made exclusively for export in Canada with 510mm (201") wheelbase, fitted with different domestic bodies (many thanks, Ilian Filipov).

|

Diamond T 975 long wheel base wheel

Canadian trucks. Holland, 1945 |

972 Dump Truck

The Diamond T chassis was also used as a basis for a dump truck known as the model 972, in addition to its other uses. The spare tires were mounted between the cab and bed. The tailgate could be opened at the top for dumping, or at the bottom for spreading. When the open cab was standardized for the Diamond T, it wasn't initially fitted to the dump. Instead, the trucks were built with the closed cab in order to exhaust the supply of pre-built cabs Diamond T had assembled.

|

| Diamond T 972 Dump Truck without winch (closed cab) |

When that stockpile was exhausted in September 1943, the dump trucks began receiving open cabs. In order to reduce front axle loading, the earliest dump trucks did not have winches.

|

| Diamond T 972 Dump Truck without winch (open cab) |

However, at the request of the Corps of Engineers, beginning in June 1944. the dump trucks were also fitted with the front winch.

|

| Diamond T 972 Dump Truck late model with winch |

Specs (truck):

| Diamond T Model 968 Cargo 4 ton, 6x6 (G509) |

|---|

| Main Features |

|---|

Built

Crew | 9.000 (cargo) 1941-45

2 |

| Length | 6.83 m |

| Width | 2.44 m |

| Height | 3.05 m |

| Mass | 12.100 kg |

| Armour | none |

| Armament | none |

| Mobility |

|---|

| Drive | Hercules RXC 6-cylinder petrol engine - 8.668 cc - 106 hp @ 2300 rpm |

| Transmission | 5 speed + 2 gear red. |

| Tyres | 9.00 x 20. |

Range

Max. veloc. | 215 km

64 km/h |

155mm Howitzer M1

History

The M1 155 mm howitzer (name changed to M114 in 1962) was a towed howitzer developed and used by the United States Army. It was first produced in 1942 as a medium artillery piece under the designation of 155 mm Howitzer M1. It saw service with the US Army during World War II, the Korean War, and the Vietnam War, before being replaced by the

M198 howitzer.

The gun was also used by the armed forces of many nations, including Afghanistan, Argentina, Austria, Belgium, Brazil, Bosnia, Cambodia, Cameroon, Canada, Chile, Republic of China, Croatia, Denmark, Germany, Ecuador, France, Greece, Iran, Iraq, Israel, Italy, Japan, Jordan, South Vietnam, South Korea, Lebanon, Libya, Norway, Netherlands, Pakistan, the Philippines, Portugal, Saudi Arabia, Singapore, Spain, Thailand, Turkey, Venezuela, Vietnam and Yugoslavia. In some countries, the M114 still remains in service.

|

| M1A1 155mm howitzer in action - WWII |

Development

A new carriage was under development for much of the 1930s for the existing World War I-era M-1918 155 mm howitzer, which was a license-built French

Canon de 155 C modèle 1917 Schneider until 1939 when it was realized that it did not seem logical to put a new carriage underneath an obsolete howitzer.

|

| M-1918 155 mm howitzer |

So development began a new with a carriage designed to be used for either the 155 mm howitzer or the 4.7-inch (120 mm) gun. This was completed by 15 May 1941 when the Howitzer M1 on the Carriage M1 was standardized. The howitzer itself differed from the older model by a lengthened barrel of 20 calibers and a new breech mechanism. Uniquely it was the sole 'slow-cone' interrupted screw mechanism to enter service after 1920. This meant that two separate movements were necessary to open the breech, versus the single movement of the 'steep cone' mechanism that simultaneously rotated and withdrew the breech. The M1A1 was redesignated as the M114A1 in 1962.

|

| M114A1 155mm in action - Vietnan |

Carriage variants

The carriage was also used by the

4.5 inch Gun M-1. It went through a number of minor changes over time. The original Warner electric brakes were replaced by Westinghouse air brakes on the M1A1. Both the M1 and M1A1 carriages used a mid-axle firing pedestal that was extended by a ratchet mechanism. The M1A2 replaced the ratchet with a screw-jack system and also modified the traveling lock. The M1A1E1 carriage was intended for use in jungle and muddy terrain and replaced the wheels of the M1A1 with a free-wheeling tracked suspension, but the project was terminated after V-J day without having reached production. The T-9 and T-10 carriages were projects using low-grade steel alloys that were canceled when no longer needed. The T-16 was a light-weight carriage using high-grade steel that was estimated to save some 540 kg; work began in July 1945 and continued after the war, although nothing seems to have come from it.

A mid-1960s variant was the 155mm XM123 & M123A1 auxiliary-propelled howitzers. The XM123 was produced by American Machine and Foundry and outfitted with two 20 horsepower air-cooled engines produced by Consolidated Diesel Corporation, driver’s seat, steering wheel, and guide wheel on the trail, allowing it to be more rapidly emplaced when detached from the prime mover, while the XM123A1 provided a single 20 horsepower motor with electric steering.

|

| Auxiliary propelled 155mm XM123 in trials |

The extra weight on the left trail displaced the howitzer after each round was fired requiring it to be realigned and the project was abandoned. The concept was copied from the Soviet 85mm SD-44 auxiliary-propelled antitank gun developed in 1954 and used by airborne forces.

The 155mm howitzer M1 used separate loading ammunition comprised of four components: a projectile, a separate bagged propellant charge, a fuse and a primer. The propelling charge contained individual bags of powder, which could be reduced or increased to adjust for range of fire.

Projectiles were stocked in wood crates or pallets; the charge was packaged individually in fibre or metal canisters. The projectiles, weighing 95 lbs. (43 Kgs) each, had rings in the tip (eyebolts lifting plugs) to assist in shipping; these were removed and replaced with fuses when ready to fire.

The primers were placed in the breech of the gun for firing. Schreier states the 155mm howitzer typically fired 80% or more HE (high explosive) shells during the war. The piece could also fire smoke or white phosphorus shells as well. The 155mm Gun M1, (Long Tom) , and the M12 Gun Motor Carriages also used the same ammunition.

Self-propelled mounts

The M1 howitzer was experimentally mounted on a lengthened chassis of the

M5 light tank. The resulting vehicle received the designation 155 mm Howitzer Motor Carriage T64.

|

| 155 mm Howitzer Motor Carriage T64 |

A single prototype was built before the T64 project was abandoned in favor of T64E1, based on the M24 Chaffee light tank chassis. This was eventually adopted as

155mm Howitzer Motor Carriage M41 and saw action in the Korean War.

|

| 155 mm Howitzer Motor Carriage T64E1 |

|

| 155 mm Howitzer Motor Carriage M41 |

Towards the end of the Korean War the US Army replaced the M41 self-propelled howitzer with the

M44 self-propelled howitzer.

|

| M44 self-propelled howitzer. |

Specs:

| M1 155 mm Howitzer |

|---|

Type

| Howitzer |

|---|

Place of origin

| United States |

|---|

Service history

|

|---|

In service

| 1942–present |

|---|

Used by

| See operators |

|---|

Wars

| World War II, Korean War,Vietnam War, Lebanese Civil War |

|---|

Production history

|

|---|

Designed

| 1939–1941 |

|---|

Manufacturer

| Rock Island Arsenal (US) |

|---|

Produced

| 1941–1953 |

|---|

Number built

| 10,300+ |

|---|

Variants

| none |

|---|

Specifications

|

|---|

Weight

| Travel: 5,800 kg

Combat: 5,600 kg |

|---|

Length

| Travel: 7.315 m |

|---|

|

| Bore: 3.564 m L/23

Overall: 3.79 m L/24.5 |

|---|

Width

| Travel: 2.438 m |

|---|

Height

| Travel: 1.8 m |

|---|

Crew

| 11 |

|---|

|

|

| separate-loading bagged charge |

|---|

|

| 155 mm |

|---|

|

| slow-cone interrupted screw |

|---|

|

| hydropneumatic system |

|---|

Carriage

| split trail |

|---|

|

| -2°/+63° |

|---|

|

| 25° left or right |

|---|

|

| burst: 4 rpm

sustained: 40 rph |

|---|

|

| 563 m/s |

|---|

Maximum firing range

| 14,600 m |

|---|

The kits:

For this project, the kit from

Mirror Models US Diamond T 968A Cargo truck (hard top cab) #35803.

|

| Mirror Models box kit |

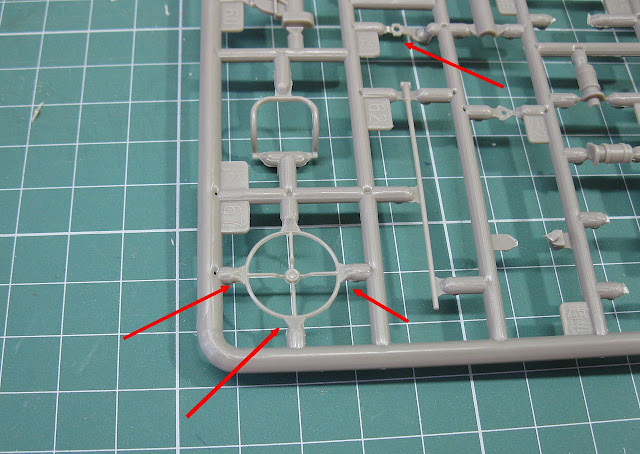

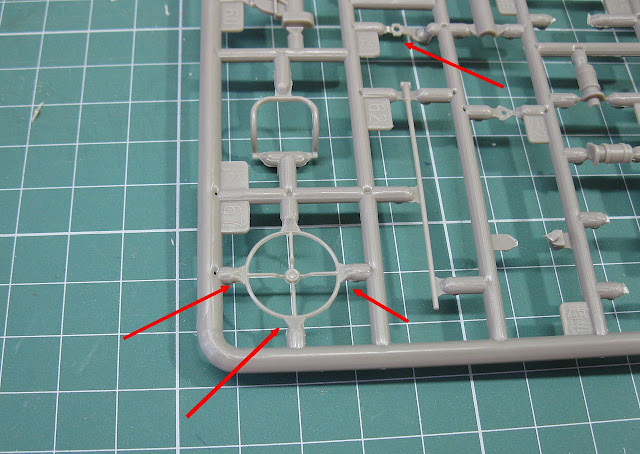

The kit is well injected, but with burrs and the pieces are attached in the trees by too wide connectors ...

|

| Burrs and wide connectors... |

It will be a lot of work cut pieces off the trees without damaging them.. Mostly small parts ...But, let's go!!!

|

| Wheels and booklet... |

|

| Wheels done...Piece of cake!! |

The engine is very well detailed!!!

|

| Hercules petrol engine. |

But the connectors are a nightmare...

|

| Big connectors and small parts: a dangerous recipe... |

You must use your cutter very away of the parts:

|

| Result: a lot of burrs to cut after ... |

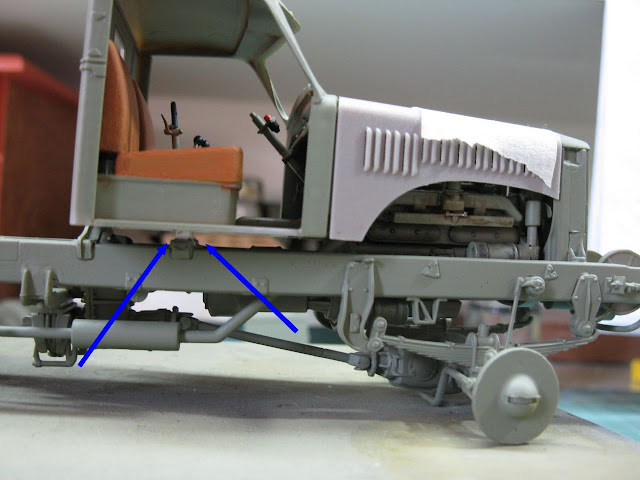

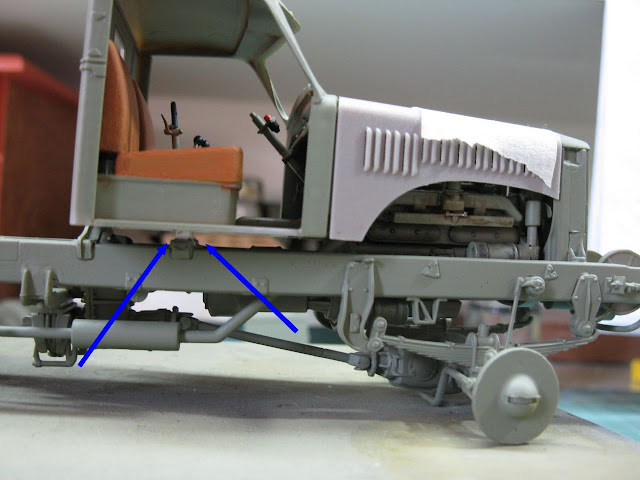

And yet the most delicate parts are suffering ....

|

| Notice the almost fracture of parts (blue arrows) |

Gents, small parts with big connectors REALLY are a combination of wrap the stomach ...work progresses slowly ....

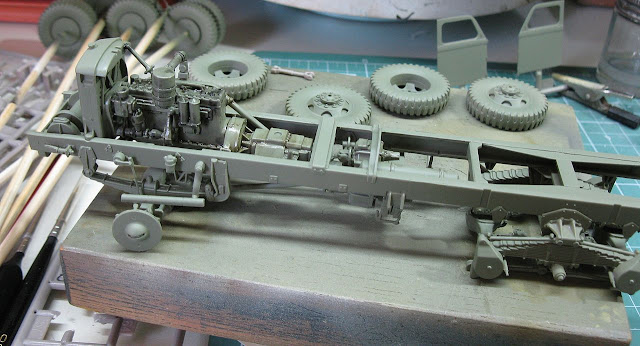

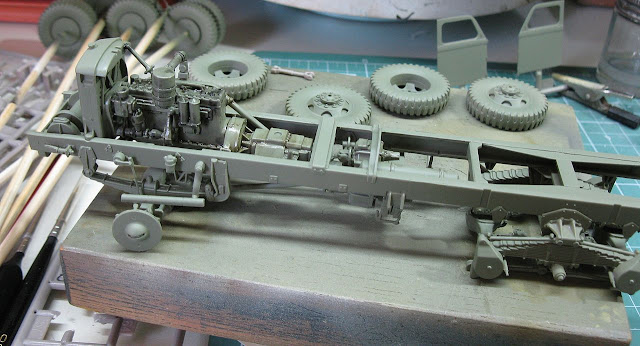

|

| Frame under construction... |

Starting the rear suspension: I decided to build the rear bogie hinged. The reason is facilitate the alignment of the wheels on the chassis. As the fittings and grooves are just listed (and unreliable ...) I decided to save headaches in the future articulating the rear suspension. Once the wheels are aligned, I'll fix it in place with glue.

|

The rear springs and the bogie's axle. Using metal wire to articulate the

suspension. |

|

| The rear suspension swinging... |

|

| The rear suspension swinging... |

As I said before, the fittings are horrible and generally undersized. This is the kind of work you have to do in most kit fittings...

|

| Planning the surgery... |

|

Surgery done...Now, the part will fit ...

A tremendous waste of time ... |

|

| The chassis is almost ready... |

Well...To relax of the chassis stress, let's build the cabin....The booklet is very confused in this step...

|

| Wall fire and dasboard: external view... |

|

Internal view. Notice that there is no hole

or marking in the floor to the steering column.

My guess: between the pedals... |

|

| Cabin and chassis painted in olive drab primer from Vallejo... |

|

| Too bad the engine will not be exposed ... |

After testing the cabin in position, I noticed that you need a shim of 1.5 mm in the chassis for it to be well aligned ...

|

| The shim... |

|

| Cabin in position ( the lips of the engine hood is the template) |

|

| The shim in position... |

|

| Cabin glued in position... |

|

| Without the engine hood... |

|

| And with hood and front fenders!!! |

|

| The girl is growing... |

|

| Installing the wheels and making the alignment of all ... |

|

| The big girl with her shoes ... |

|

| Decidedly, is not a kit for beginners !!! |

Growing and growing...

|

| Cargo bed and metals... |

|

| Windshields... |

And the girl goes on...

|

| Olive drab - primmer |

|

| Future to prevent silvering... |

While the Future dries, I will adapt the vacuform canvas: It is necessary to cut the front and rear portions...

|

I used cyanoacrylate to glue the tracing paper...

After that, I used PVA glue and water in the paper |

|

| The canvas painted with PET primer |

Markings: Diamond T Model 968A cargo truck - 4 ton - 6x6 (G509) - Artillery prime mover - 1st Armored Division (US Army) - 27th Field Artillery Batallion - Battery B, 26th vehicle - Italy, 1944.

|

| The vacu-canvas is interesting... |

But, when I started to build this huge girl, I found these pics in th internet...

|

Diamond T 968 cargo landing of an LST in Boungainville.

Notice the M-1918 155 mm howitzer being towed... |

|

Diamond T 968 cargo towing an

155mm M1 howitzer in Italy. |

...I remembered that I have an old and archaic M1 155mm howitzer from Testors in my closet...So, let's try give life to this old and primitive thing, in parallel with the building of the truck.

|

| Older than the sketch of the Bible ... |

|

| My relic !! |

|

| The howitzer and the prime mover... |

But then, you ask to me: Why waste time with this old kit, if there in the market this little beauty ??

|

Bronco M1A1 155mm howitzer

Notice the Diamond as prime mover. |

And the answer is: because I have the old kit in my closet and is very, very fun to turn pig ears into silk purses!! For me, build model kits is in essence... fun !!!

|

| The building is easy... |

Improving the oldstuff:

|

improving the equilibrator springs...

cutting the plastic... |

|

Cooper wire and dremel

in manual rotation |

|

| New springs done... |

|

| In position... |

If you really intends to improve this kit to decent conditions, check out this excellent article: in the

US Army Model site.

I will not completely rebuild the kit because I intend to put tarps and load on the howitzer, seemed like the picture below:

|

| Notice the canvas and cargo... |

|

| Almost decent... |

|

Notice the Diamond's spare wheel in

the howitzer's trail |

|

| The Girl with her fang !!! |

And now, a tip: Thanks to my wife (who loves making crafts and scrapbook), found a substitute for rare and expensive MVlenses: Something called Rhinestone clear flat. Are little pieces of mirrored acrylic, similar to the MVlenses. Self-adhesive and with different diameters and colors. The type "dome" is smooth, which are the most suitable. Do not buy the faceted parts.

|

| Rhinestone clear flat in various colors and diameters |

I bought with

this seller in eBay (have no relationship with them ...). There must be other vendors. I do not know the durability of them, but seem fantastic ...

|

| The headlights made with scrapbook stuff... |

|

| in close... |

|

| Glued in place with PVA glue... |

|

| Amazing... |

|

| The moorings of canvas made with polyamide thread. |

|

| Almost there... |

Putting things in the howitzer ...

|

| Stuff from my spare parts box... |

|

| Protecting the breech from road's dust... |

|

| Painted... |

And my Girls were ready: Diamond T Model 968A cargo truck - 4 ton - 6x6 (G509) - Artillery prime mover - 1st Armored Division (US Army) - 27th Field Artillery Batallion - Battery B, 26th vehicle ; towing an 155mm M1 howitzer, in Italy, 1944.

|

Diamond T Model 968A cargo truck - 4 ton - 6x6 (G509) - Artillery prime mover

1st Armored Division (US Army) - 27th Field Artillery Batallion

Battery B, 26th vehicle Italy, 1944. |

|

| Diamond T Model 968A cargo truck - 4 ton - 6x6 (G509) - left side |

|

| Diamond T Model 968A cargo truck - 4 ton - 6x6 (G509) - right side |

|

| Diamond T Model 968A cargo truck with Kojak and Rover, the dog. |

|

| 155mm Howitzer M1 |

|

| 155mm Howitzer M1 - left side |

|

| Diamond T 968A prime mover with 155mm Howitzer M1 |

|

Diamond T 968 with Sherman M4A1 for size comparison...

The girl is huge !!! |

|

Diamond T Model 968A cargo truck - 4 ton - 6x6 (G509) - Artillery prime mover

1st Armored Division (US Army) - 27th Field Artillery Batallion

Battery B, 26th vehicle Italy, 1944. |

See you, soon...in my next project !!!