Drivers!!!

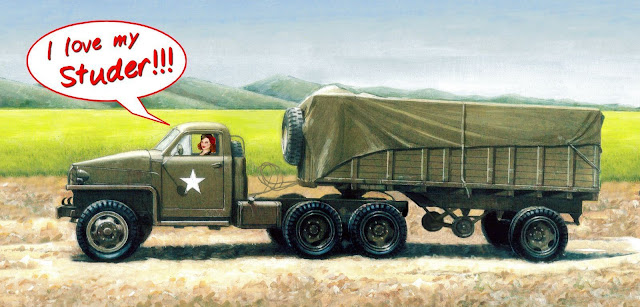

Today we are going to tell you a bit about the history of a brave family of trucks that helped (and very ...) the Allied victory on many fronts. Let's talk about the Studebakers and especially their tractor version, the

Studebaker US6 - U6 6x4 tractor.

|

| Studebaker US6 - U6 - 6x4 tractor with 7-ton semi-trailer. |

|

Two Studebakers US6 - U6 - 6x4 tractor with 7-ton semi-trailers.

Normandy - 1944

Photo by courtesy of Mike Haines.

|

History:

The Studebaker US6

(G630) was a series of 2½-ton 6x6 and 5-ton 6x4 trucks manufactured by the

Studebaker Corporation and

REO Motor Car Company during World War II. The basic cargo version was designed to transport a 2,300 kg cargo load over all types of terrain in all kinds of weather.

|

| Studebaker US6 - U - 6x6 - 2½-ton cargo truck. |

Most of these were exported to the Soviet Union under

Lend-Lease by the USA during World War II, since the competing

GMC 6x6 CCKW design proved to be more suitable for Western Front conditions.

|

| GMC CCKW 353 - 6x6 - 2½-ton cargo truck. |

Design and development:

A total of 219,882 2 1⁄2-ton (2,268 kg) 6x6 trucks and similar 5-ton (4,536 kg) 6x4 versions in thirteen variations were built. Studebaker was the primary manufacturer, which built 197,678 of them at their South Bend IN plant, while REO produced 22,204 more at their Chicago IL plant from 1944 under a sub-contract. REO trucks are identical to Studebakers, but REO only built cargo-model trucks with the long wheelbase and without the front-mounted winch, more specifically referred to as the US6 U9. All production by both manufacturers ended in 1945.

Service:

The US6 was manufactured primarily for export under Lend-Lease. The Soviet Union would become the largest foreign operator. The first Studebaker US6 trucks arrived in the USSR in the autumn of 1941.

|

A threadbare Studebaker US6 in russian hands.

Ivan loved this truck !!! |

The Red Army organized a test of eleven 6x6 "

Studebekkers" (as they become referred to in the USSR) which took place between July 1942 and May 1943. The results were used to direct the enlargement of the payload from 2 1⁄2 tons (2,300 kg) to 4 tons (3,600 kg). In 1945, it was lowered to 3 1⁄2 tons (3,200 kg, although on improved roads they could carry up to a maximum of 5 tons (4,500 kg).

Large numbers of Studebaker US6 trucks were supplied to the Soviet Union via the

Persian Corridor in Iran under the USA's Lend-Lease program.

|

A long line of Studebakers US6 - U6 - 6x4 tractor with 7-ton semi-trailer

rest a little, observed by Iranian women, somewhere in Persian Corridor

June, 1943. |

The truck fulfilled many important roles in the Red Army, such as towing artillery pieces and anti-tank guns and transporting troops over long distances. It was renowned for its overall ruggedness and reliability, including its reliability on poor-quality fuel.

|

| A Studebaker US6 full loaded with Ivans and towing an artillery gun. |

The Red Army also found them to be a suitable platform for conversion into Katyusha rocket launchers. The truck became affectionately known as the

Studer by Soviet troops and was even recognised by Joseph Stalin, who sent a letter of appreciation to Studebaker, in which he thanked them for the superb quality of the US6 for Soviet service.

|

Studebaker US6 with field adaptation fuel tank

refueling a long range medium-bomber Yermolayev Yer-2

Russian front, Winter, 1943. |

Studebaker US6 trucks were also used by the US military in the construction of the

Burma Road and the

Alcan Highway in North America.

|

| Chinese National soldiers wave to a Studebaker US6 passing on the Burma Road |

|

Studebaker US6 - U9 with isothermal vans was used by the US Army

Alaskan Highway. 1943 |

|

| A Studebaker poster about Alaskan Highway. |

Postwar the US6 strongly influenced the USSR's design of the

ZiS/ZiL-151, which, in turn, evolved into the

ZiL-157.

|

Zis- 151-2 prototype. Notice the resemblance to the Studebaker

Built in Spring, 1946 |

|

| Zis- 151-1 prototype. Built in Autumn, 1946 |

|

| Zil-157 - first production - 1958 |

Description:

The US6 used a Hercules JXD engine, with an 5.200 cc

L-head inline 6 cylinder gasoline engine developing 86 hp (64 kW) at 2800 rpm and 271 N⋅m of torque at 1150 rpm. A conservative-type and highly-reliable engine with a compression ratio of only 5.82:1, it could use 72-octane gasoline. This same engine was also used in the M3 half-tracks and, later, M8 Greyhound and M20 armoured cars (the latter was a variant (lacking the gun turret) of the M8 Greyhound).

The Warner T 93 5 speed transmission had a very low first, a direct fourth and an overdrive fifth gear. A power take-off could be fitted to operate a winch (mounted just below in front of the radiator) and/or the hydraulic hoist on dump trucks (the U10/U11 and U12/U13 dump truck models).

The Timken T-79 transfer case had high and low ranges, a neutral position and could either engage or disengage the front axle, in the 6x6 versions. There was one output shaft mounted forward to the front axle (not used in 6x4 trucks) and two to the rear, with one for each rear axle. Both front and rear axles were of the Timken split-type with a ratio of 6.6:1. The front axle had ball-type constant-velocity joints while the two at the rear were full-floating.

The US6 had a ladder frame with three beam axles, the front on semi elliptical leaf springs, the rear tandem on quarter elliptical leaf springs with locating arms.

There were two wheelbases, the short 148 inches (3.76 m) - (Short Wheel Base: SWB), used in semi tractors, dump trucks, and short cargo models, and the long 162 inches (4.11 m) - (Long Wheel Base: LWB), used in tankers, long cargo models, and the U9 chassis cab (measurements are from the centerline of the front axle to the centerline of rear bogie). All models had 7.50-20” tires and dual rear tires. 6x4 models, intended for on road use only, were rated at 5 tons (4536 kg), twice the 6x6’s off-road rating.

|

Studebaker chassis - Long Wheel Base

6x4 and 6x6 versions |

The US6 carried the design of Studebaker’s civilian truck cab, although it was modified for military use. Studebaker trucks were different from other 2 1⁄2 6x6 trucks built for the war effort of the USA because vent windows were included in each door. These vent windows were separate from the main window that rolled down into the door-frame and could be swung out to help with the truck cab's ventilation.

|

| Studebaker US6 cabin - notice the vent window (red arrow) |

Studebaker also designed the open-type military truck cab which was featured on the GMC CCKW (later models), but their major customer, the USSR, preferred the closed cab for their generally harsh (cold-weather) climate. While Studebaker's open-type truck cab became the American standard, production of the US6 with the closed-type truck cab was restarted after only 10,000 units of the former.

|

| Studebaker US6 U open cabin - a rare girl... |

|

A rare Studebaker US6 U4 open cabin with winch

leading Studers closed cabin without winch.

Bucharest, 1944. |

- The U1 and the U2 cargo trucks (which had a frontally-mounted winch) had a short wheelbase and the spare tire was mounted behind the cab, thus allowing a truck-bed measuring only 2.74 m long. These “prime mover”-style bodies were not a success as the US6 was to be mainly used for transporting cargo.

|

Studer US6 U1 (no winch) and U2 (with winch). U.S. Army - 1941

Notice the spare wheels behind of the cabin |

- The U3/U4 6x6 and the 6x4 U7/U8 cargo trucks had a longer wheelbase, which allowed the spare tire to be mounted under the 3.66 m truck-bed.

|

Studer US6 U3 for the British Army - Notice the lack of left headlight.

Factory picture - 1941. |

|

Studer US6 U4 with (rare) hatch in the top of cab for .50 Browning MG

overturned in Stiwell Road - Kunming, 1945. |

|

Studer US6 U7 (6x4) captured by the Germans

crossing a river with rubber boats - Russian front, 1942. |

|

| Studer US6 U8 (6x4) - Russian front, 1943. |

- The U5 tank truck had a long wheelbase and a two-compartment 750 U.S. gal (2,800 l) tank mounted on the truck-bed. Tanker trucks were not equipped with winches.

|

| Studer US6 U5 gas tank truck. |

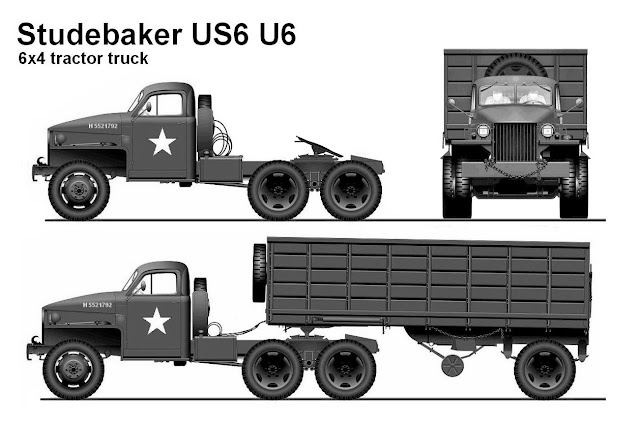

- The U6 6x4 semi-tractor was the only semi-tractor version in the entire US6 truck series. Semi-tractors have limited off-road performance and, therefore, the U6 was rated for a 5-ton load on improved roads. For this same reason, they had no frontally-mounted winch. Versions with metal (hard top) and soft cabin.

|

Studer US6 U6 tractor with the Edwards D-11-B semi-trailer (hard top)

Moscow - 1944 |

|

Two British Studebakers US6 U-6 6x4 tractors

The young soldier on the left is Frank David Hitchford (born 1925 - died 1978)

driver of the Royal Army Service Corps (RASC) - Holland - 1944

I don't have the identification of the other two soldiers... sorry.

Thanks to Dave Thacker for the photo and story of this brave lad!! |

|

Studer US6 U6 tractor with soft cabin

Pic: Courtesy of Roy Chow |

- The U9 cargo truck had a long wheelbase and lacked a frontally-mounted winch. The Soviet Katyusha multiple rocket launcher could be mounted on their truck-beds (most of the US6 trucks in Red Army service were of the U9 model).

|

| Studer US6 U9 - Workshop shelter - 1944. |

|

Studer US6 U9 - BM-13 Katyusha in parade

Moscow - 1945. |

- The U10/U11 (end-type) and the U12/U13 (side-type) dump trucks had a short wheelbase. Both types had the dump-body mounted on a sub-frame at the rear of the truck, with the end-type dump having a hydraulic cylinder attached to the chassis with a lever arrangement while the side-type dump had the hydraulic cylinder mounted directly to the truck body.

|

| Studer US6 U10 - Dumper truck with rear unloading |

|

| Studer US6 U12 - Dumper truck with side unloading |

Production and dimensions:

| Studebaker US6 - U6 tractor 6x4 |

|---|

| Type | 5-ton 6x4 tractor truck |

|---|

| Place of origin | United States of America |

|---|

| Production history |

|---|

| Designer | Studebaker |

|---|

| Manufacturer | Studebaker |

|---|

| Produced | 1941–1945 |

|---|

| No. built | 8.640 |

|---|

| Specifications (U6 Tractor 6x4) |

|---|

| Weight | 3.714 kg - empty |

|---|

| Length | 5.26 m |

|---|

| Width | 2.21 m |

|---|

| Height | 2.18 m - top of cab |

|---|

|

| Engine | Hercules JXD 86 hp @2.800 rpm |

|---|

| Transmission | 5 spd. x 2 range trf. case |

|---|

| Suspension | Beam axles on leaf springs |

|---|

Operational

range

| 400 km |

|---|

| Speed | 72 km/h |

|---|

The kit:

For this project, my choice wass the good kit from ICM Studebaker US6 U4 (#35514). As the US6 U6 didn't have winch, the option for model U3 would be correct. Luckily, the ICM's U4 kit has the U3 parts (no winch version).

|

| My workbench, the kit and my fellas: Kojak and Rover!! |

Firstly, we have to know the differences in dimensions between the U3 (cargo) and the U6 (tractor) versions.

|

| Dimensions of my version: Studebaker US6 U6 tractor and 7 ton trailer. |

|

Notice the differences between the SWB and LWB: 14" or 356mm.

In 1/35 scale, the difference is 10,1mm (1,01cm) |

Therefore, the wheelbase should be reduced by 10.1mm. I'm going to cut a segment with these dimensions on the stringers of the chassis:

|

| The first cut done!!! |

|

| The portion of 10,1mm cut out the stringers... |

|

The rebuilt stringer: 10.1 mm shorter.

Alignment in gluing is critical. |

|

| The chassis in his "shorter" version... |

|

| The engine in the chassis... |

About engine, I hate to waste a nice detailled part inside a closed bonnet. My choice: reproduce the lower (and visible...) portions of the power train with reversible hydrocolloid and cast a "fake" engine with dental acrylic.

|

Using the model kit engine as a master.

The master in the reversible hydrocolloid jelly |

|

| Waiting for the hardening of the jelly with the hydrocolloid cooling ... |

My recipe of casting material: graphite powder to to add color to the acrylic... You add 10% graphite to 90% acrylic (polymer) powder ... and blend with liquid acrylic (monomer). You pour this self-curing acrylic in the form of hydrocolloid ... and wait 10 minutes for acrylic polymerization.

|

| And so we have another good product from the Panzerserra Foundry Company |

|

| The powder mixture... |

|

| The mixed powder with liquid acrylic (monomer)... |

|

| The acrylic hardening. This process is exothermic ... It generates a little heat ... |

And Frankenstein breathes !!! It's alive ... it's alive !!!

|

| My Frankenstein is alive!!! |

Now, it's time to reduce the length of the drive shafts: the same 10.1mm. And we must not forget to eliminate the drive shaft for the (non-existent) front wheel drive. The tractor model uses a single axle.

|

| Cutting the axes ... |

|

| Cutting the rear drive shafts and the front one eliminated... |

|

| The new transmission for the "shorter" tractor... |

The Studer US¨U6 front axle is the result of an exchange of parts between kits: I'm going to use the single axle of an ICM Ford V3000 and I'll keep the axle with differential for a future version of the Ford V3000 4x4 Marmon-Herrington. "In modeling, nothing is lost, everything is reused" !!

|

| Making the 6x4 Studer version with another ICM stuff... |

|

| The new US6 U6 6X4 chassis, with transmission train and stering system... |

|

| On your feet, soldier!!! |

With the problem of the chassis sorted out, let's build and paint the interior of the cabin...

|

| Painting the chassis... |

|

| The dashboard of cabin..The rear view mirror is in scratch |

|

| Oh, ICM!! Shame on you!!! |

It's time to reproduce one of Studer's most striking features: the vent windows in the doors. I will cut the transparent parts with the cutting disc of my Dremel. Here is a dangerous step: for the part and for the fingers of this one who writes to you !!

|

| The transparences and the plan of the surgery... |

|

| The surgery done... |

|

| Wes...we have vent windows!!! |

|

| For the Motherland!!! |

|

| Ivan is a very happy guy!!! |

|

| With snout!! |

|

| Almost a truck!!! |

Well...after checking the dimensions of the US6 U6 tractor's chassis, I realized that the wheelbase was correct, but the chassis was still long... The correct measurements:

Comparing with the photos and diagrams, I realized that the rear portion of the chassis needed another cut :

|

| Cutting at 157,8mm |

|

| The corrrect lenght!!! |

|

| Done!!! |

|

| The new part in Plastruct (green arrow) . Notice the putty (1,8 tons...) in the cabin's top.(red arrow) |

|

| New rear lamps ...Open the holes... |

|

| Rear lights in position...from my spare parts box!!! |

|

| Scratchin the spare wheel rack...and the tool box in the side of the chassis... |

|

| Hmmm...Much better!! |

|

| Scratching the fifth wheel and the reinforcements of the shorter chasssis... |

|

| The fifth wheel was cute ... and it moves !!! |

|

| Some measurements, in millimeters ... |

|

| The rear guides for the fifth wheel... |

|

| Again, some measurements, in millimeters ... |

|

The front aspect, of the fifth wheel... Sorry..

This pic was taken later, after painting...I forgot to

show the profile of the fifth wheel.... |

|

The side aspect, of the fifth wheel... Sorry..

This pic was taken later, after painting...I forgot to

show the profile of the fifth wheel....

|

|

| And the cut on the rear spar, to allow the kingpin of the trailer does not impact on this region ... |

|

Two tractors, side by side...Autocar 7144T and Studer US6 U6...

Nice girls!!! |

Some advances in the tractor: after looking at the photo above, I noticed that the Autocar had a wooden deck in the chassis, just after the cabin ... This gave me the idea of doing the same in my Studer: a field adaptation, to increase the cargo area ... Let's scratch...

|

| I wonder: why not?? |

|

| The additional wooden deck: plasticard carved like wood ... |

|

| In position: Borat approves!! |

I decided to do my Studer with British markings, by Jove !!!

|

Sooooo cute!! Notice the gas cans on top of fuel tank...

Soooo British!!! |

|

| Other features of the English version: Blackout single (left) headlight |

|

British Studers have:

Single headlight (left side and blackout type) - green arrows

Bridge markings - red arrow

Misterious plate with markings - blue arrow

Lanterns at the ends of the front fenders - yellow arrows |

|

| The girl with trailer...Testing...testing... |

|

| Next step: Painting!!! |

As I said before, my girl will be British: Thanks to

Mike Haines, for this amazing picture and

Richard Pearce for the decisive help with identifying the AoS (Arms of Service) of the photo: Studebaker US6 U-6 tractor 6x4 belonging to the 21st British Army Group -

Royal Army Service Corps (RASC) - 536 GT Company - 11 June 1944, Normandy - France.

|

Studebaker US6 U-6 tractor 6x4 - 21st British Army Group

Royal Army Service Corps (RASC) - 536 GT Company

11 June 1944, Normandy - France. |

Olive drab:

|

Who says the olive drab is boring ???

Left side |

|

| Right side |

After the painting dried, I began to make the chalk markings of the D-Day landing with white gel pen in the front bumper(see pic below) and on the rear of the trailer (my guess...):

|

| Chalk markings on the front bumper... |

|

| Next step: decals. |

|

| Decals made with my Lasercolor... |

|

| Decals in place. |

Now, I'll wait for the white markings numbering and name: DESTRUCTOR... But in the meantime, let's continue with Studer Tractor. I found this photo on the Internet and it gave me some interesting ideas:

|

Studebaker US6 U-6 with 7 ton trailer

Notice the rollbags in the rear and fender.. hmmm |

Well, since there is this historical precedent, we will put some accessories of

Value Gear in this girl. I simply love these accessories ... I have lots of Value Gear sets in my closet ... The good thing is to look for the sets compatible with the project in question.

|

| Value Gear in the fenders... |

|

| And in the rear of the Studer... |

Value Gear stuff after cleaning, stuck in a paint base with double-sided tape. I like to paint sets for several kits in one step. These acessories will make an up-grade in the

Ford G917 double-cabin and in the

Studer snow-plow.

|

| Value Gear stuff waiting primer... |

|

| White primer...I really do not understand the black primer's "fashion" ... |

|

| Value Gear stuff after painting... |

|

| And in the Studer tractor: front view |

|

| Rear view... |

|

| The Tractor and his trailer...almost there!! |

Finally, my request of "white decals" landed in my workbench! These are the individual markings of the "DESTRUCTOR" as well as the registration numbers. The decals provided by my great friend

Fabio Melo, the famous

Fabinho !!!

Thanks, Fabinho!!!

|

| The "white decals!!! |

|

| Fabinho's gift!!! |

|

And the DESTRUCTOR was born!!!

next: weathering!!! |

Windshields and dust!!

|

| Notice the rope in the front bumper... |

And my girl was readt: Studebaker US6 U-6 tractor 6x4 "DESTRUCTOR" belonging to the 21st British Army Group -

Royal Army Service Corps (RASC) - 536 GT Company - 11 June 1944, Normandy - France.

|

Studebaker US6 U-6 tractor 6x4 "DESTRUCTOR"

21st British Army Group - Royal Army Service Corps (RASC)

536 GT Company - 11 June 1944, Normandy - France.

|

|

Studebaker US6 U-6 tractor 6x4 "DESTRUCTOR" with

Kojak and Rover, the dog. |

And the composition: Studebaker US6 U-6 tractor 6x4 "DESTRUCTOR" with

7-Ton American Semitrailer, Panel Cargo.

Keep'em rolling!!!

|

Studebaker US6 U-6 tractor 6x4 "DESTRUCTOR" with 7-Ton American Semitrailer, Panel Cargo.

21st British Army Group - Royal Army Service Corps (RASC)

536 GT Company - 11 June 1944, Normandy - France.

|

|

|

with Kojak (very happy, although it does not look ...) and Rover, the dog.

|

|

Studebaker US6 U-6 tractor 6x4 "DESTRUCTOR" with 7-Ton American Semitrailer, Panel Cargo.

21st British Army Group - Royal Army Service Corps (RASC)

536 GT Company - 11 June 1944, Normandy - France.

|

Keep'em rolling!!!