Soldaten und Bauern!!!

Our character today is a vehicle that, in the first instance, could never be considered a military vehicle. Let's talk about a rough, noisy, smoky weird farm tractor with a huge single-cylinder engine capable of burning almost anything, from diesel, crude oil, kerosene, vegetable oils and even lard. The character of our article is the Lanz Bulldog, a tractor that was born for the field and the farm, but was requisitioned by the German Government to serve in the German War effort in WWII. Come with me and meet this unusual, humble and irreplaceable warrior.

|

| Lanz Bulldog tractor D 8506 HR7 - 1938 Agrarmuseum Wandlitz -Brandenburg, Germany. |

History:

The Lanz Bulldog was a tractor manufactured by Heinrich Lanz AG in Mannheim, Baden-Württemberg, Germany. Production started in the early 20s, in the 20th Century, right after the WWI.

|

| Heinrich Lanz AG plant |

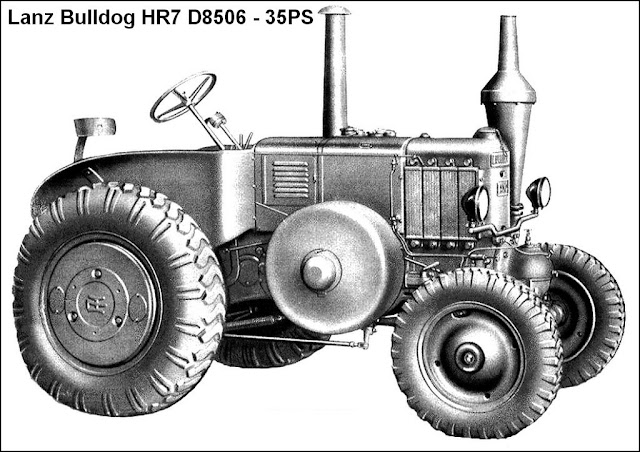

Various different versions of the Bulldog were produced up to 1960, one of them being the tractor Lanz Bulldog HR7 D8506 .

In 1921, the first 12 hp Lanz Bulldog, developed by Fritz Huber, was introduced to the market.

|

Fritz Huber - mechanical engineer - Father of Bulldog born: 8 March 1881 - Wasserburg am Inn - Bavaria, Germany died:14 April 1942 - Mannheim, Germany. |

The incredible characteristic of the Lanz Bulldogs in being multi-fuel, that is, burning cheap and superfluous fuels is still not surpassed by other types of tractors. The single-cylinder hot-bulb engine happily burned heavy oils such as tar, distillation residues such as naphtha and mazut, and other unusual oils (including vegetables) for which there was no use in the combustion of a vehicle until then.

The tractor was named BULLDOG because of its compact, stocky, and robust appearance.

|

| The first of many: Lanz Bulldog 12 hp - 1921 |

|

| Heavy-oil engine BULLDOG An image from a 1921 brochure with a Lanz Bulldog 12 hp as power source for agricultural machinery |

And since it could be operated like a multi-fuel tractor, with its engine burning cheap crude oil and other "heavy" flammable fuels in a post-WWI era and into the Great Recession of the 1930s, its appearance was what we can call a product perfect for the right season. Its success and manufacturing continuity during this period are proof of this assertion. The Bulldog with its hot-bulb engine was considered more reliable than the first diesel tractors of that time.

|

| Heinrich Lanz Company logo |

|

Schematic cutaway drawing, showing major technical details of a Lanz Bulldog Heinrich Lanz Company. |

|

| Cutaway model of a Lanz Bulldog to illustrate the tractor's technology of construction |

In terms of other matters such as traction, technology or fuel consumption, the Bulldogs were almost similar to contemporary diesel tractors, but a little inferior. Despite this, Lanz Bulldog tractors were able to stay on the production line for many decades (at least in Germany) because their 2-stroke hot-bulb engine was cheap to produce and required little fuel ignitability and resistance to detonation. The simplicity and practicality, combined with the robustness of the vehicle allowed Heinrich Lanz AG to sell the vehicle in a consistent manner, and the tractor concept evolved over the years, becoming an example of commercial success that lasted decades , mainly in Germany.

See the table below to see the main types of Bulldog tractors manufactured by Lanz from the 1920s until near the end of World War II.

|

| * In 1936 Lanz changed the performance data from "normal continuous output" (DL) to " maximum output over an hour "(HL). Thus, on paper, the 30 HP (PS) Bulldogs became a 35 HP Bulldog. |

The Lanz Bulldog D8506 (the main character of this article) had the characteristic of a chassis-less construction, one-piece with the engine and transmission forming its backbone. It featured a rear drive axle and a dead front axle. The front axle could have a bundle of semi-elliptical springs as an option.

|

| Lanz Bulldog HR7 D8506 with suspension in front axle - cross section Notice the single cylinder horizontal engine |

The tractor could be equipped with inflatable rear tires, solid rubber or metal rims, with additional grapples for greater traction. The D8506 does not have a lockable differential. The gearbox was a Lanz 3-speed manual gearbox with reverse gear, with an auxiliary gearbox, which represented the doubling of the number of gears (6 forward and 2 reverse). The top speed was 3.3 km/h in first gear and 16.7 km/h in sixth gear. The drum brakes on the rear wheels were foot operated, with the handbrake acting on the gearbox.

|

| Lanz Bulldog gear box view |

The Lanz Bulldog engine was the standard hot-bulb type with a displacement of 10.3 liters. The engine was cooled by the thermosiphon system.

From the D8507 series on, it had a better speed regulator, and from the D9506 series onwards it was available as an option to start the engine by electric starter. If a starter motor is used, the lead battery would have a capacity of 94 Ah. Without a starter motor, the battery capacity was 75 Ah.

The Lanz factory offered several additional accessories, such as a semi-open or closed cabin (like a car) or continuous fenders.

|

| Lanz Eilbulldog (Express Bulldog) HR7 D8539 - 35HP The "high speed" road/farm model, with closed cabin and continuous fenders |

The standard Lanz Bulldog was a hot-bulb engine and was developed by the engineer Fritz Huber from around 1918 . It works according to the Akroyd process with internal mixture formation and external ignition (so, it's not a diesel engine).

Unlike the original four-stroke Akroyd engine, the Bulldog engine ran on two strokes with a wet crankcase. The engine's compression ratio was low, no higher than the compression ratio of gasoline engines at the time.

Therefore, the engine did not have the self-ignition characteristic of diesel engines, but needed an ignition source. The so-called hot-bulb in the cylinder head served as this ignition source: it was heated with a torch to red to start the engine's initial combustion. The fuel was injected into this hot-bulb at low pressure, where it evaporated and ignited on the hot walls of this bulb, starting the typical rotation of these engines.

|

| A blow-torch being used to heat the engine's hot-bulb of a Lanz Bulldog tractor |

If the hot-bulb temperature drops too low (for example, due to the engine idling for a long time), it may happen that the temperature of the hot-bulb walls (which serve as an ignition source) is no longer sufficient to start the engine ignition safely, so that the engine shuts off. See this video below:

To avoid this problem, some later variants had spark plugs that could ignite a "cold" engine with gasoline, and then the fuel could be switched to diesel or other oils, with the engine warmed up. In these later versions, the spark plugs and fuel nozzles were located in the cylinder head.

Operation and working cycle

The cycle starts with the piston at the bottom of its stroke. As it rises, it draws air into the crankcase through the inlet port. At the same time fuel is sprayed into the vaporiser. The charge of air on top of the piston is compressed into the vaporiser, where it is mixed with the atomised fuel and ignites. The piston is driven down the cylinder. As it descends, the piston first uncovers the exhaust port. The pressurised exhaust gases flow out of the cylinder. A fraction after the exhaust port is uncovered, the descending piston uncovers the transfer port. The piston is now pressurising the air in the crankcase, which is forced through the transfer port and into the space above the piston. Part of the incoming air charge is lost out of the still-open exhaust port to ensure all the exhaust gases are cleared from the cylinder, a process known as "scavenging". The piston then reaches the bottom of its stroke and begins to rise again, drawing a fresh charge of air into the crankcase and completing the cycle. Induction and compression are carried out on the upward stroke, while power and exhaust occur on the downward stroke.

|

| Lanz Bulldog engine fuel injection pump in cross section |

A supply of lubricating oil must be fed to the crankcase to supply the crankshaft bearings. Since the crankcase is also used to supply air to the engine, the engine's lubricating oil is carried into the cylinder with the air charge, burnt during combustion and carried out of the exhaust.

|

| Lanz Bulldog hot-bulb engine in action |

The oil carried from the crankcase to the cylinder is used to lubricate the piston. This means that a two-stroke hot-bulb engine will gradually burn its supply of lubricating oil, a design known as a "total-loss" lubricating system. There were also designs that employed a scavenge pump or similar to remove oil from the crankcase and return it to the lubricating-oil reservoir. Lanz hot-bulb tractors and their many imitators had this feature. This reduced oil consumption considerably.

|

| Circulating lubrication with Fresh oil addition, low lubricating oil consumption One filling of the lubricating oil container is sufficient for a full working day of 10 hours. (from Lanz AG brochure) |

In addition, if excess crankcase oil is present on start up, there is a danger of the engine starting and accelerating uncontrollably to well past the speed limits of the rotating and reciprocating components. This can result in destruction of the engine. There is normally a bung or stopcock that allows draining of the crankcase before starting.

The lack of valves and the doubled-up working cycle also means that a two-stroke hot-bulb engine can run equally well in both directions. A common starting technique for smaller two-stroke engines is to turn the engine over against the normal direction of rotation. The piston will "bounce" off the compression phase with sufficient force to spin the engine the correct way and start it.

This bi-directional running was an advantage in marine applications, as the engine could, like the steam engine, drive a vessel forward or in reverse without the need for a gearbox. The direction could be reversed either by stopping the engine and starting it again in the other direction, or, with sufficient skill and timing on the part of the operator, slowing the engine until it carried just enough momentum to bounce against its own compression and run the other way.

|

| Hot-bulb Bolinder's engine with single cylinder maritime use |

|

| A 1922 pamphlet about maritime Bolinder's Oil Engines |

This was an undesirable quality in hot-bulb-powered tractors equipped with gearboxes. At very low engine speeds the engine could reverse itself almost without any change in sound or running quality and without the driver noticing until the tractor drove in the opposite direction to that intended. Lanz Bulldog tractors featured a dial, mechanically driven by the engine, that showed a spinning arrow. The arrow pointed in the direction of normal engine rotation; if the dial spun the other way, the engine had reversed itself.

Lanz Bulldog tractors in WWII:

The outbreak of World War II was not so dramatic for Lanz AG Meinhein at first. Lanz, as Germany's largest farm machinery manufacturer, was allowed to continue producing and selling its tractors to the civilian market, almost without obstacles. The objective was to maintain the food production line intact.

|

| Lanz Bulldog in his "nest": a barn on a German farm, in 1939. |

But even agricultural tractors attracted the attention of the military. Several manufacturers have had their machines tested and Lanz, with its reputation for robustness and reliability, was no exception.

|

| A civilian Lanz in its natural habitat. Notice the Wermacht car, parked just behind. Maybe a requisition inspection?? |

|

| A Lanz Ackerbulldog HR5 15-30 being tested on a farm by a German soldier. Family photo or a requisition test... |

The German Reich military became more interested mainly in the tractors of the Eilbulldog line, due to their speed and versatility, were tested and acquired for the function of traction of heavy loads. In this context, the Luftwaffe was the one that most received the Lanz Bulldogs, for work involving towing aircraft and cargo handling at aerodromes. But Wermacht also received many tractors, of different models, from Lanz, including some models with tracks. These small tractors had an enormous traction capacity, not rejecting any heavy work...

|

| Do you need to pull an urban tram??? This is a job for a Lanz Bulldog!! |

|

| Is your problem big, heavy and bulky bales?? The solution is a Lanz Bulldog!! |

|

| Or would they be huge and heavy sets of auxiliary power machinery?? Call for a Lanz Bulldog!! |

|

| And so the military doesn't get jealous, how about carrying a lot of cargo for the Wermacht???? This is a job for a Lanz Bulldog!! |

|

| A civil Lanz Bulldog towing military personel in trailers France - 1940 |

|

| Maybe the inspiration of this Lanz Bulldog MiniArt kit (#35314) has been the image above... |

|

| War prize !! Lanz Eil-Bulldog towing a captured Canon de 155 L modele 1916 Saint-Chamond french gun France - 1940 |

|

| Luftwaffe's Lanz Eilbulldog HR8 D9538 The driver is very happy with his toy... |

|

This Luftwaffe Lanz Eilbulldog HR9 D2531 is towing a cargo trailer Notice the German officer's flight suit in the foreground. |

|

| Lanz Acker-Bulldog HR8 D9500 towing a Stahlfeldwagen Hf. 7 trailer of Wermacht being transported in a railway car to the Russian Front |

|

| Lanz Eil-Bulldog HR9 D2531 with camouflage February 1943 |

|

| Lanz Bulldog HR8 D8506 with snow chains in the rear wheels. Russian front - Winter 1942. Wermacht |

|

| A desolate Luftwaffe soldier contemplates his Lanz Bulldog stuck in the ruthless Russian Rasputitsa. Operation Barbarossa - April 1942. |

|

| Did someone happen to mention mud, around??? A Lanz Bulldog with metal wheels with claws for better traction on "sticky" terrains, sparing german soldiers from the discomfort of Russian Rasputitsa. |

|

| A tracked Lanz Raupe-Bulldog HRK-55PS D1571 in the Russian winter - 1941 |

|

| A tracked Lanz Raupe-Bulldog HRK-55PS D1571 flattening an icy runway in the Russian winter. Take a look at the various Junkers Ju-52 transports. |

|

Lanz Raupe-Bulldog HRK-55PS D1571 towing a Henschel Hs-129 ground-attack aircraft in a muddy russian airfield |

|

| Lanz Eilbulldog HR9 55PS from Luftwaffe with closed cabin. The tractor was being prepared to tow a glider DFS 230. Italy, 1943. |

|

| American captured Lanz Bulldog D8531 with continuous fenders pulling two trailers through Sancoins, France, at the beginning of September 1944 |

|

| A famous photo of a truck depot near Baupte, Normandy, discovered by the 508th PIR (Parachutte Infantry Regiment) - 82nd Airborne Division June 12, 1944. In the foreground, a Lanz Kühlerbulldog HR6 22/38 PS |

|

| Lanz Kühlerbulldog HR6 22/38 PS left view in close up |

With war efforts and food requirements pressing for increasingly mechanized farming, sales of the Lanz Bulldog in Germany continued to grow. In 1942 Lanz set out to commemorate the incredible feat of the 100,000th Bulldog produced, but the celebration was limited by the death of the so-called "Father of the Bulldog", engineer Fritz Huber, on April 14 of that year.

While Lanz's production numbers were still impressive, the company's heyday began to fade. Although the hot-bulb engine principle was mechanically correct and very suitable for the 1920s and 1930s, with the development of the technology, the difference in the relative power of hot-bulb engines compared to the now more improved diesel engines began to make yourself noticed.

This was especially felt after the Nazi government's 1942 ruling that all tractors should be converted to wood gas (gasogen) to save fuel for military efforts. Although Lanz engineers were able to make this adjustment, the power loss was very critical for the simple and primitive hot-bulb engines.

|

| Lanz Bulldog D7506 - Notice the engine power dropped from 35 to 25 hp |

The conversion of the engine from hot-bulb to gasogen is carried out, but with some technical problems. Initially, the engineers employ the method of mixing two fuels, that is, a small amount of fuel oil was injected into the gasogen-air mixture that was sucked into the cylinder, in order to start combustion.

|

| Wehrmacht soldier in a rearfront with a Lanz Ackerluft Bulldog D7506 equipped with a wood gas system |

But the typical aspiration of the air-fuel mixture through the crankcase of a two-stroke engine caused serious problems of contamination of the lubricating oil by the gasogen, resulting in damage to the bearings. Only the introduction of a special gas valve in the engine's air-gasogen mixture supply line provided a satisfactory solution. Power loss was critical in early models (early series dropped from 35 to 25 hp), but by 1944, the engines had returned to near-normal power levels.

|

| Lanz Eil-Bulldog HRG9 D2539 Holzgas with 55HP in the late models- 1943 |

This slightly damaged the Bulldog's reputation for robustness, hurting sales and production, with the Allied bombing raids did the rest. In 1945, over 90 percent of the buildings in the Mannheim plant were destroyed. Many employees lost their lives or were seriously injured, but production was quickly resumed with the means available.

|

| A B-24 Liberator "Bombers Moon" of the 489th Bombardment Group releases bombs over Mannheim, Germany, Oct. 3, 1944. |

With the end of the war and the division of Germany into occupation zones, Lanz began its reconstruction, trying to restart the production of tractors, but with the exhaustion of the state by war, there was a chronic shortage of resources. There were no financial means for new developments and technologies. Lanz therefore had to restart production with the pre-war models with which they had experience.

|

| Lanz - The pioneer Company cover pamphlet from 1948 |

Competing companies on the other hand, were much luckier: Fendt in Marktoberdorf was hit by just one bomb. Furthermore, agricultural machinery manufacturers previously insignificant to Lanz, such as Eicher, Schlüter, MAN, Deutz, Hannomag and IHC, have become much more active and developed. Because of its rebuild, Lanz had to stick with hot-bulb engines, while other factories had more resources to develop more economical and easier-to-use four-stroke diesel engines.

John Deere purchased Lanz in 1956 and started using the name "John Deere-Lanz" for the Lanz product line.

|

| John Deere-Lanz Model Q 40PS - 1960 it was one of the last models made with the Lanz Bulldog pattern before John Deere completely overhauled the factory's production. |

A few years after the Bulldog was discontinued the Lanz name fell into disuse. The Lanz Bulldog was one of the most popular German tractors, with over 220.000 of them produced in its long production life. The name "Bulldog" is widely used in Germany as a synonym for tractors even today, especially in Bavaria.

The Lanz Ackerluft Bulldog HR7 D8506

This version was built from 1937 to 1944, with minimal variations:

- Compared to the HR5 / HR6, the controller and the fan drive have been relocated to the left side of the engine (the exhaust side)

- The injection pump was still driven on the right-hand side via the so-called thumb shaft

- A simplified Bosch oiler was attached below the crankshaft

- From tractor no.: 130642 - replacement of the jaw coupling with the large disc coupling

|

| Lanz Bulldog HR7 D8506 - early |

- From tractor no.: 626058 - replaced by the further development, the small disc clutch

|

| Lanz Bulldog HR7 D8506 - late |

Remarks and model details:

- 6 forward speeds, thus best adaptation to the most varied of ground and load conditions.

- Air tires for the fields ensure constant operational readiness for use in the field and in the road without changing the wheels.

- Easy coupling and quick shifting thanks to the single-lever clutch, just like in a car.

- Coarse maneuverability, equally advantageous in the field (small headland) and in tight areas.

- Immediate readiness to start thanks to electrical ignition (optional)

- Electric lighting with an indestructible steel battery.

- Well-sprung seat with upholstery.

- Convenient lever arrangement from left to right in the following order: handbrake, clutch pedal, control column, footbrake, accelerator pedal, hand throttle.

- Spacious platform for taking small devices with you.

- Large fuel tank for 90 liters of heavy fuel oil.

- Protected storage of individual parts under a removable hood, the closure of which is the dashboard: air filter, oil can, battery, ignition coil, fuse box, switch box, Bosch horn.

- Bosch oiler under flywheel guard (left).

- Pulley drive with idle. Right-hand pulley, left-hand exhaust.

- Protected space for the guide by connecting the shell fenders to the dashboard.

- Suspended front axle (semi-elliptical springs).

- Tires: fourfold pneumatic tires, rear wheels with farm air tires.

D85xx versions:

- D8500: early version Acker Bulldog with 3-speed gearbox, handbrake and hand throttle

- D8506: standard version Ackerluft Bulldog with 6-speed gearbox, pneumatic tires, hand and foot throttle, hand and foot brake, electric lighting system and starter ignition, front-axle springs

- D8511: Combibulldog, pneumatic or elastic tires, six-speed gearbox, hand and foot throttle, hand and foot brake, electric lighting system and ignition, front-axle springs

- D8531: Eil Bulldog with six-speed gearbox up to 22 km/h, high-speed road model - road tires, front-axle springs, electrical lighting system and starter ignition, continuous fenders, upholstered bench seat

- D8532: combination model for road and field use, front-axle springs; cabin with metal roof

- D8539: high-speed road model like D8531, but with closed cab.

| Type | Years of production | Tractor numbers |

|---|---|---|

HR7-30 PS | 1935-36 | 125001 -... |

HR7-35 PS | 1937-39 | ... |

HR7-35 PS | 1940-44 | 625001 -... |

|

| Lanz Ackerluft Bulldog tractor HR7 D8506 35PS with cargo trailer with Luftwaffe markings and personel France - 1944. |

|

Restored Lanz Bulldog HR7 D8506 with rounded cabin from D8532 |

Specs:

| Lanz Bulldog HR7 D8506 35PS | |

|---|---|

| Overview | |

| Type | Tractor |

| Manufacturer | Lanz Bulldog |

| Also called | Ackerluft |

| Production Number built | 1921 -1955 (all types) + 220.000 (all types) |

| Assembly | Mannheim, Baden-Württemberg Germany |

| Powertrain | |

| Engine Bore/Stroke | Hot-bul 35HP@540rpm one-cylinder, 10.3 liters 225 x 260mm |

| Transmission | 6-speed manual |

| Propulsion | Tyres (air, solid or metal) |

| Dimensions | |

| Wheelbase | 1975 mm |

| Length | 3400 mm |

| Width | 1780 mm |

| Height Weight | 2185 mm 3800 Kg |

| Ground.clearance top speed | 315 mm 16,7 Km/h |

| Chronology | |

| Predecessor | HR6 series D 8506 |

| Successor | HR8 series D 9506 |

The kit:

For this commission project, I'll use this new and interesting kit: German tractor with cargo trailer (#35317) from MiniArt.

|

| Beautiful box art from MiniArt |

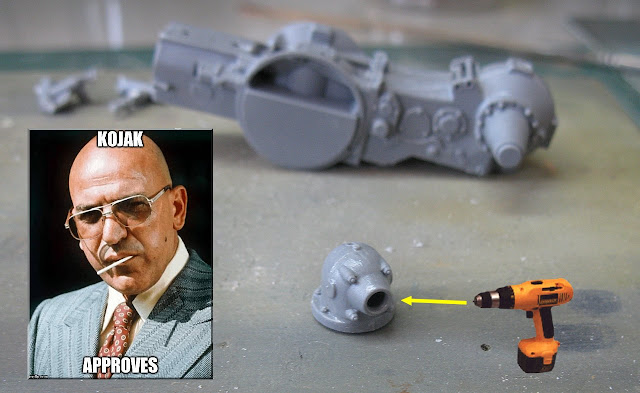

After the wise advice of the old Kung Fu Master Pai Mei, let's start the job: always following the booklet, starting by the engine / chassis:

|

| Kojak overseeing the start of tractor's building... |

|

| The rear and front parts of the engine/chassis (left to right) |

|

| The step 3 contains a challenge: only for experienced modelers... Man, the kind of phrase that Kojak just loves... |

|

| The opening of the 0.3mm diameter holes was carried out smoothly and serenely. The bald one is really happy... |

|

| The holes, in close-up... |

|

| ...and Kojak also took the opportunity to remove the plastic (fixed) tow hook, which will be replaced by a removable metal one. All holes drilled in this step, in yellow. |

|

| The engine/chassis, in "belly" view. Notice the white rod.I replaced the original part with something more "straight". |

|

| And the engine/chassis with "engine hood" in position. Right view |

|

| Engine/chassis with "engine hood" in position. left view |

And now, a little frisson moment, as my kit came with the piece Da10 missing. It's a delicate piece, with some details, but I molded a similar piece (Da15) with dental alginate and solved the problem, casting a new piece with polymerizable dental acrylic

|

| Oh, man...it's all right, now!! |

Continuing with the "challenge" of MiniArt, with the installation of very thin copper wires (0,2mm) in the holes previously executed, with a drill and scalpel. Kojak installed the copper wires with a minimum amount of cyanoacrylate, then carefully bend the wires with tweezers, until their correct positions...

|

| The bald one is happy as nobody!! |

|

| Kojak's little details... |

When we started scratching, we didn't stop anymore... The seat spring part (Eb7) now looks very rough to us... how about replacing this plastic piece with something more detailed??

|

| The new metal spring done... |

|

| To install the new spring is easy: just glue two pieces of Plastruct round rod (0,8mm diameter) to serve as a fitting for the new spring... |

|

| The new spring in the seat's rod fitting (superglue) and... |

|

| The new spring with seat in position!! Indeed, much better!! |

|

| Continuing the construction of the sub-assemblies: the exhaust will be painted separately, to facilitate the finishing... The air intake "chimney" will be painted in the same color as the vehicle... |

|

| Rear view of Lanz cabin... The rear rack is installed and lined up... |

|

| Right side view |

A small-big detail: be careful when gluing the rear tire treads: they can be glued in any direction position and you can inadvertently glue the tire treads so that the tires have the changed chevrons when installing on the tractor. Look at the figure in detail, so that the chevrons "point" in the same direction...

|

| Steps 20 and 21: notice the tire treads... the chevrons must "point" to the same direction (step 21)... The front wheels don't have this problem... |

|

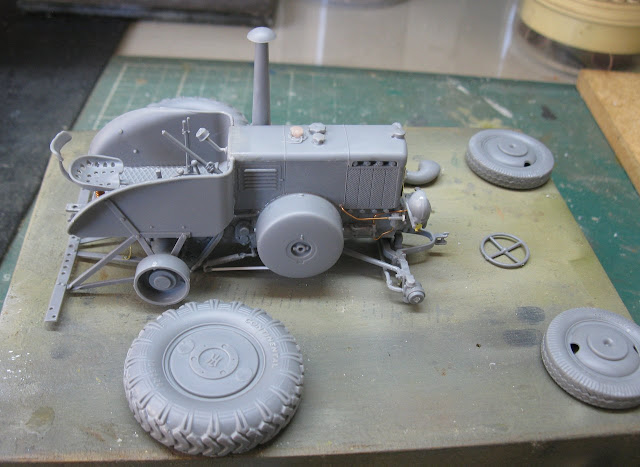

| The tractor with the construction completed, awaiting the painting and marking phase... |

|

| Lanz Bulldog tractor : right view |

|

| Lanz Bulldog tractor :belly view |

|

| Lanz Bulldog tractor :front view |

|

| While we wait for the tractor's glue to dry completely, let's begin construction of the trailer |

|

| All parts fit together beautifully, without warping or twisting. Very well done, Ms. MiniArt!! Congratulations!!! |

|

| The rear suspension is very well detailed!!! A real eye candy!!! |

The front part of the trailer is very delicate. The rotation device it has to be built very carefully, without any burrs, so that it can rotate freely. The thing is complicated because the parts are thin and fragile, but just follow the manual carefully and everything works wonderfully...But everything is very fair and without gaps...

|

| Be very careful when building the rotation device, my Precious!!! |

|

| Checking the perfect squareness... |

|

| And the trailer was done!! |

|

| Now, the best part: markings and painting!!! |

As usual, I like to research a lot about the vehicles I build. I don't necessarily reproduce original photos, but I like to use real photos as time and place references to locate my girls in time and space... And based on that, check out this photo I found on the Internet: a Lanz Bulldog working in an airbase, with a Focke-Wulf FW 200 Condor.

|

| A might Focke-Wulf FW 200 Condor with Lanz Bulldog HN3 D7506 20PS towing a fuel trailer Notice the tractor is without the vertical exhaust pipe |

I don't know about you, but every time we talk about the Focke-Wulf FW 200 Condors, I immediately remember the Group that were called the Atlantic Terror: the Kampfgeschwader 40 (KG 40), from Bordeaux-Mérignac!!!

I really don't know if the photo above is of the Focke Wulf 200 Condor of the KG 40, from Bordeaux-Marignac, but the historic connection is already made in my mind: My Lanz Bulldog was working in France in 1941 with these elegant four-engine, hauling cargo and fuel for the Kampfgeschwader 40! Something like this:

After primer, shades of Panzer Gray... Man, this is very exciting... |

| Shades of Panzer-Gray... left side. |

|

| Panzer-gray: right side. |

|

| Wheels and exhaust system... |

|

| Crates and fuel drums... |

|

| A slight touch of camouflage... Chameleon Rules!!! |

|

| After a few thin layers of Future, it's time to apply the decals... The beautiful KG 40 badge and FLAMMABLE |

|

| Applying white backgrounds to highlight the colors of the decals in the little tractor... |

|

| Mixture of decals from Panzerserra and MiniArt... Kojak is becoming fully satisfied... |

|

| Luftwaffe vehicle!!! |

|

| KG 40 tractor... right side... Notice the small black decal above the fuel injector... |

|

| Cabin decals that the instruction sheet does not indicate... |

|

| Trailer decals: a mix of Panzerserra, MiniArt and spare decals... No Smoking! and FLAMMABLE - left side |

|

| License plate, FLAMMABLE, max speed and Keep Distance 50m |

|

| Trailer decals: FLAMMABLE and No Smoking! - right side |

|

| All parts togheter...starting the weathering... |

|

| The trailer, standing on its own paws... |

|

| Trailer, left side |

|

| Trailer, rear view |

|

| Trailer, right side |

|

| Trailer, front view... the tow bar is still very clean... |

|

| Lanz Bulldog, with with the start of weathering... It really is a soooo beautiful vehicle!! |

|

| Lanz Bulldog - left side |

|

| Lanz Bulldog - rear cabin view |

|

| Lanz Bulldog - right side |

|

| The composition, under inspection of Kojak... |

|

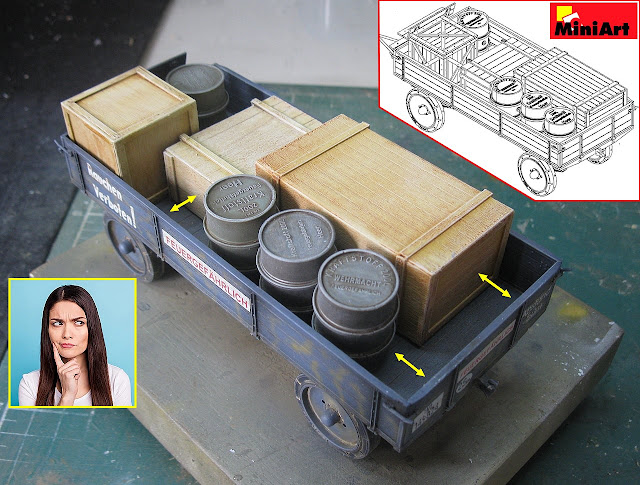

| Testing the positioning of the load on the trailer... Hmmmm...In the MiniArt design, the load is a little tighter, almost no empty spaces (see yellow arrows)... |

|

| But, as always, Value Gear is here to save the day!!! Man, I love these accessories!! Much, much better!!! |

|

| And a dry-run of the project. |

|

| Notice the steering wheel/starting lever in wood... |

|

| Headlights in position... |

|

| The trailer, full loaded: boxes, wooden planks and fuel barrels, all properly packed and well distributed.... |

|

| Keep your distance!!! |

And, with that, we can say that the project is finished!!

I present to you Lanz Ackerluft Bulldog tractor HR7 D8506 35PS with cargo trailer, providing support service in the Kampfgeschwader 40 (KG 40) in Bordeaux-Mérignac, France, in January 1941.

|

| Lanz Ackerluft Bulldog tractor HR7 D8506 35PS Kampfgeschwader 40 (KG 40) - Bordeaux-Mérignac. France - January 1941. |

|

| Lanz Ackerluft Bulldog tractor HR7 D8506 left side |

|

| Lanz Ackerluft Bulldog tractor HR7 D8506 3/4 left rear view |

|

| Lanz Ackerluft Bulldog tractor HR7 D8506 3/4 rear right view |

|

| Lanz Ackerluft Bulldog tractor HR7 D8506 right side |

|

| Lanz Ackerluft Bulldog tractor HR7 D8506 3/4 front right view |

Here's a little (!) problem: the crew provided by MiniArt wears Wermacht uniforms and there is no Luftwaffe crew option... The crew was built and painted, but please be aware that I know what the following scene is about from a loan of the vehicles of the KG 40 to the garrison of the Werhmacht in Bordeaux-Mérignac

|

| What is a Wehrmacht soldier doing on a Luftwaffe tractor?? |

|

| Even the bald one was also curious... |

|

| This is what I call companionship between arms!!! |

|

| The figure adapts very well to the kit... |

|

| As it is a figure injected in plastic, the set is quite acceptable... Too bad I don't wear Luftwaffe uniforms... |

|

| And the trailer, with cargo...I tried to make the tow bar swivel, but the fit is very, very fragile. The option was glue fixation. |

|

| Cargo trailer - bird view |

|

| Cargo trailer - 3/4 left rear view |

|

| Cargo trailer - 3/4 right rear view |

|

| Cargo trailer - right view |

|

| Lanz Ackerluft Bulldog tractor HR7 D8506 35PS with cargo trailer Kampfgeschwader 40 (KG 40) - Bordeaux-Mérignac, France. January 1941. |

|

| What are these guys looking at??? |

|

| Some Luftwaffe official must be yelling: Return this tractor IMMEDIATELY!! |

|

| Ouch... Things got complicated... Notice the Mercedes-Benz L6500 4x2 heavy truck tankwagen, from the same KG 40 Squadron, in the background... |

| |

|