Over there!!

Ladies and Gentlemen, let's talk about a multinational tank, which was even known by the name International. It was born from an unprecedented concept of a joint war effort between nations but which, with the end of hostilities in 1918, did not have the opportunity to demonstrate its real capabilities on the battlefield. We are talking about a great pioneer in the history of armored vehicles. Today is the day to talk about the Mk VIII Liberty- International heavy tank.

|

| Meanwhile, at Camp Meade - Maryland... circa 1921. |

|

| The pilot British Mark VIII Liberty tank Notice the rear side exhausts, characteristic of this first tank. mid 1918 |

History:

The Mark VIII tank also known as the Liberty or The International was a British-American tank design of the First World War intended to overcome the limitations of the earlier British designs and be a collaborative effort to equip France, the UK and the US with a single heavy tank design.

Production at a site in France was expected to take advantage of US industrial capacity to produce the automotive elements, with the UK producing the armoured hulls and armament. The planned production levels would have equipped the Allied armies with a very large tank force that would have broken through the German defensive positions in the planned offensive for 1919. But in practice, manufacture was slow and only a few vehicles were produced before the end of the war in November 1918.

After the war, 100 vehicles assembled in the US were used by the US Army until more advanced designs replaced them around 1932. A few tanks that had not been scrapped by the start of World War II were offered to Canada for training purposes.

|

| Several American Liberty tanks being prepared for shipment to Canada - 1940 |

Development of an idea:

As the First World War progressed, the industrial production capacity of the Entente was taxed to the limit. Of the Allies, only Great Britain and France had been major industrial nations in 1914 and the latter had lost 70% of its heavy industry when the Germans overran that part of Lorraine that they had not already occupied in 1871.

When the United States of America declared war on Germany on 6 April 1917, many in Britain hoped this event would solve all these problems. The two men directly responsible for British tank production, Eustace Tennyson d'Eyncourt and Lieutenant-Colonel Albert Gerald Stern, initially considered sending a delegation to the United States immediately, to convince the new ally to start production of a British tank design.

|

| Sir Eustace Henry William Tennyson d'Eyncourt Sir Albert Gerald Stern |

After some reflection they decided it was best to leave the initiative to the Americans. Stern did contact the American Military Attaché in London immediately after war was declared. In June 1917 the first American approaches were made, but not by the US Army as they had expected. The US Navy wanted the most modern tanks for its US Marine Corps.

At that moment the current British tank project was the Mark VI. It was designed with existing British industrial capacity in mind, posing limits that might be overcome by larger American production facilities.

|

Mark VI - British heavy tank - front left view Wooden mockup - 1917 |

|

Mark VI - British heavy tank - rear left view Wooden mockup - 1917 |

|

| Mark VI heavy tank - artistic concept |

Lieutenant-Colonel Stern therefore pretended that an even more advanced project had already been in existence which he called the Mark VIII (there was also a much more conventional Mark VII project). He invited the Americans to participate and contribute as much as they would like to its design. The Navy was on the brink of sending a team of engineers to Britain when the American Department of War was informed of developments by the US Military Attaché in London. It ordered the project to be shifted to the Army and selected Major H. W. Alden – in peacetime he had been an industrial expert – to go to the UK to work with the Mechanical Warfare Department design team at Dollis Hill on the first drawings of the new tank. He arrived in London on the 3 October, 1917, to discover that a lot of design work had already been done by Lieutenant G. J. Rackham, who had been sent to the Front to see for himself how the current designs performed in the dismal conditions then encountered at the battlefield in Flanders.

%20%20used%20as%20the%20roof%20of%20a%20dug%20out.%20Zillebeke,%2020%20September%201917.jpg) |

Tank knocked out in the Third Battle of Ypres Battle of Passchendaele - used as the roof of a trench. Zillebeke - Flanders, 20 September 1917 |

The International tank

The US Army had set up headquarters in France. In September it decided to form its own tank corps with 25 tank battalions including five heavy tank battalions. To equip the heavy units, Major James A. Drain – a staff officer to General Pershing and responsible for initial planning of the tank force – provisionally ordered 600 Mark VI tanks (then under development) from the British in October 1917. The Army tried to convince the Department of War to divert all available tanks to the Army, leading to a conflict with the Navy (the first of many to come over this issue). This posed serious problems for the British government. It now seemed that American involvement in the war would mean a lesser number of tanks available for the British forces. Also on 4 February 1917 binding agreements had been made with the French about tank production. These had to be renegotiated.

Winston Churchill, the new Minister of Munitions, had just been forced to fire Stern as director of the Mechanical Supply Department (Controller of the Mechanical Warfare Department) because of his mistakes in handling the Mark IV project, leading to enormous production delays. In pushing production through in the early days he had upset civil and military authorities.

|

| The Minister of Munitions Winston Churchill meets female workers at Georgetown's filling works near Glasgow. during a inspection - 9 October 1918 |

Lieutenant-Colonel Albert Gerald Stern was appointed in September to the new position of "Commissioner for Mechanical Warfare (Overseas and Allies Branch)" in order to coordinate tank production with the US and France. Stern went to France to meet the French Minister of Munitions, Louis Loucheur and the American commander-in-chief, John Pershing. Loucheur made it clear from the beginning that France had nothing to offer in terms of existing production facilities.

|

| Louis Loucheur General John J. Pershing |

This came as no surprise to Stern who had already prepared an "International Plan" of ten points (in fact a bilateral agreement between the US and Britain) that he now managed to get accepted by the Americans. He submitted this to Churchill on the 11 November. Its main points included (using the original terminology):

- The incorporation of a partnership between the US and Great Britain for the production of 1.500 heavy tanks to be erected in France.

- The supply of a number of these tanks to France to further the higher purpose of Allied unity, should she require them. The British hoped that the French would be able to put into production their own super-heavy tanks Char FCM 2C in sufficient numbers, but Loucheur already knew this was unlikely to happen.

- France might supply an erecting shop, if convenient; in any case it might be wiser to build a new one (so a completely new factory would have to be built in France).

- A joint supply of components: Britain would supply guns, ammunition, and armour; the USA engines, transmissions, forgings, and chains (employing US car industry).

- The design would be based on British experience and American ideas and resources, and eliminate most of the faults in current tanks in power, loading, and trench crossing.

- Major Alden would collaborate to finish the working drawings before Christmas enjoying full cooperation of the British; the design was to be approved by both nations.

- Unskilled labour might be provided by imported Chinese; the French government ensured their local accommodation.

- Production would begin in April 1918 and finally reach 300 a month (so the number of 1.500 was only preliminary).

- The project would have high priority in regards raw materials, labour, factories, and transport.

- Management would be in the hands of two Commissioners, one British (Stern himself) and one American; but the French could appoint their own if their interests were concerned.

The plan already contained a specification: the tank should have a 300 hp (220 kW) engine, weigh 39 tons and have a trench crossing capacity of 4.3 m. The 11 November briefing included the first use of the word "Liberty" for the tank which was taken from the engine chosen.

The first design conference took place on 4 December at GHQ in France and Churchill approved the plan soon afterwards. It was made into a formal treaty signed by the British Foreign Secretary Arthur Balfour and the US Ambassador Walter Hines Page on 19 January 1918.

|

| British Foreign Secretary Arthur James Balfour US AmbassadorWalter Hines Page |

The treaty specified the programme in great detail. The first 1.500 tanks had to be made by the end of the year and the factory should be capable of expansion to 1.200 a month. Both goals were very ambitious given the fact there was neither a completed design nor a factory and that British tank production would in fact be 150 a month during 1918.

The United States would supply: the engine; radiator; fan; piping; silencer; lighting; dynamo; battery; propeller shaft; transmission, including gearbox; brakes; roller sprockets; gear shift and brake control; track links and pins; rear track sprockets, hub and shafts; front idler hub and shafts; track roller, track spindles and bushings.

Britain would supply: bullet and bomb-proof plates; structural members; track shoes and rollers; guns, machine guns and mountings; ammunition racks and ammunition.

The agreed price was to be £5,000 per vehicle. In December 1917 the Mark VI order was cancelled ensuring that the Mark VIII would be the new standard Allied weapon.

Tank production

United Kingdon:

In April 1918, the British formed the Manchester Tanks Association, a conglomerate of 25 local companies under the control of West's Gas Improvements Ltd, which would manufacture the hull parts and other components, for the British contribution to the program. But due to the War, the shortage of materials and labor delayed this process a lot. And all this effort practically became redundant with the end of the World War I, in November.

The Americans decided to build around 1.500 Mark VIII tanks in the USA for their own use, while in Great Britain it was decided to build another 1.450 for the British Army. the latter would be equipped with the 300 hp Ricardo V12 engine and production started in the North British Locomotive Company workshops in Glasgow, but this too was stopped by the Armistice. Plans were also underway to prepare part of the National Projectile Factory at Cardonald in Glasgow to build a further 335 tanks, managed by William Beardmore and Company, while it was decided to order a further 810 from the Metropolitan Carriage, Wagon and Finance Company in Birmingham. In fact, none of these production lines were carried out, except at the North British Locomotive Company, where sources report that 24 tanks were completed, of which six were taken into British tests. The mild steel prototype with a Rolls-Royce engine was tested on 11 November, the day of the Armistice.

|

| Pilot Mark VIII Liberty tank on an overhead crane in the North British Locomotive Company Ltd. Queens Park Works - Glasgow Notice the markings in the side of the hull. |

|

| The same Mark VIII Liberty tank seen above, in mild steel armour. Notice the rear side exhausts, characteristic of this first tank. mid 1918 |

One of these six vehicles underwent extensive testing on the roads around Bovington in Dorset, in early 1919; the fate of the other five was not recorded.

|

| British Mk VIII Liberty tank CITY OF BRADFORD VII under trials Notice the absence of the exhaust pipe on the rear side of the tank, which characterizes this being a production vehicle |

|

| British Mk VIII Liberty tank n° 12007 Tank Museum - Bovington. |

France:

The French government hoped to receive 700 Mark VIIIs for free, as the French superheavy tank, the Char FCM 2C, could not be produced in sufficient numbers, if at all. However, suffering from a lack of manpower and raw materials the French were not forthcoming in providing any facilities for the production of the International Tank. Soon the Americans decided to build a brand new assembly factory at Neuvy-Pailloux, 200 miles south of Paris, contracting a British company. Far from producing its first tank in April, the factory was not even finished by June. In August they contracted another British firm. It finished the factory in November, by which point the war had already ended; not a single tank would be built there.

|

| Tank Mk VIII factory at Neuvy-Pailloux - France An example of a big waste of time and money... early 1919 |

United States:

In July 1918, a Mk VIII with mild steel hull was manufactured in Britain and shipped to the United States, for installation of the engine and power train.

|

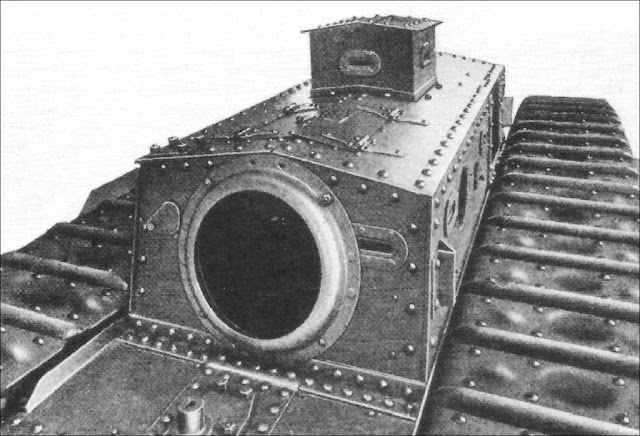

| Mk VIII tank without secondary armament. Notice the exhaust in its primitive form, coming out in the rear side of the hull. |

On arrival it transpired that no mass-produced parts were ready to finish the prototype, so the Locomobile Automobile Company in Bridgeport, Connecticut made these all by hand, completing the first vehicle on the 28 September. Testing began on 31 October of 1918, with the tank showing the armament ( two 6 pdr. guns and ten Hotchkiss machine guns) shipped from Britain.

The tank went through several tests and several successful public presentations. Although these tests showed highly positive results, the continued use revealed the need for a number of small but significant modifications. As an example, we can mention that the engine exhaust system exiting through the lower rear portion of the hull left the engine compartment floor extremely hot. This was resolved by relocating the exhaust pipes and silencers to the rear-upper part of the tank, exposed to the weather.

|

| The Mk VIII pilot tank. Notice the primitive exhaust system... |

The World War I ended before full production could be achieved, but in early 1919, Colonel Harry B. Jordan, then commanding officer at Rock Island Arsenal, received orders to assemble 100 Mark VIII tanks at that location. These tanks would use 100 sets of component parts purchased from Britain. On 2 February 1919, the mild steel Mark VIII pilot arrived at Rock Island, to serve as a comparative model for production tanks.

%20march%201919%20USA%20with%20.303%20mg.jpg) |

| The same Mk VIII pilot tank, seen above with .303 Hotchkiss machine guns installed. The tank shows the "american" semaphore mast. Notice the rear exhaust in the side rear of the tank. March - 1919 |

|

| Here, the pilot Mk VIII tank with .30 Browning MG installed in the side of the turret. Later, on production vehicles, this combat station would be deleted from American tanks May - 1919 |

The construction of the first Mark VIII at Rock Island Arsenal started on 1 July 1919 and by 1 September, general assembly of the vehicles was underway with as many as 28 tanks being built at the same time.

|

| Mk VIII Liberty tank The tank n° 5 under construction in Rocky Island Arsenal 5th December, 1919. |

|

| Assembly area of Rocky Island Arsenal. Mk VIIIs tanks under construction. Notice the little 6 ton M1917 ligt tank between heavy tanks |

|

| The Mk VIII under construction in USA. The upper deck is open, with Liberty V12 engine visible in this shot. Notice the exhaust gas system, on the sides of the upper chassis |

The first American Mk VIII tank was ready on January 5, 1920 and the last of the 100 ordered was delivered on June 5, 1920. As with every production of a new vehicle, some setbacks arose during construction and the field tests. For example, one of these initial problems was fires caused by fuel backflow through the carburetor. Fortunately, these fires were easily brought under control by the fire extinguishers that were available inside the vehicle. An unusual accident happened during the boarding of a tank in a railroad car, on March 22, 1920. The wagon threshold gave way to the weight of the tank and it rolled, falling upside down.

|

| Loading new Mk VIII tanks onto rail cars, shipped from the Rocky Island Arsenal to Camp Mead, Maryland - 22, March - 1920. Notice the Mk VIII turned upside down in the left (yellow circle) |

Fortunately, the driver and the tank mechanic who were inside the vehicle were not injured, being only shaken by what happened. Traction cables were attached to the vehicle and another tank managed to return the tank to its position. The vehicle managed to return to the workshop with its own engine. The only damage was a slight dent in the roof of the fixed turret (the commander's cupola was retracted for transport) and a bent semaphore pole. All damage was repaired, and the roof was fixed without the need to dismantle this part of the tank. These 100 Mark VIII tanks were used by the Americans in training exercises in an infantry support role, in Camp Meade - Maryland.

Description:

With a total length of 10,367 meters, the Mark VIII was a larger version of the typical British rhomboidal tanks that preceded it, all of which were designed to allow maximum optimization in trench crossing action.

|

| Size comparison between the Mk IV and the Mk VIII heavy tanks |

And even though they were larger than their predecessors, an even longer version of the standard Mark VIII tank was designed, the Mk VIII* (Star) version.

During 1918, the then prevalent preoccupation with trench crossing capabilities led to preparations being made for the production of an even longer tank: the Mark VIII* (Star). The hull was to be lengthened a full three meters: 1.2 m at the front and 1.8 m at the back, with a total length of 13,41 meters. This way it should be able to cross a trench 5.5 m wide. To ensure that the tank could turn at all, despite its critically high length-width ratio, the bottom profile of the tracks would be more strongly curved, so that a smaller part of the track would touch the ground. Ground pressure would have increased however, as total weight reached 42.5 tons (43.2 tonnes). If the tank had sunk into soft ground somewhat, it's questionable whether it would have been able to make a turn. No prototype was built.

The armament of the pilot version of the Mark VIII consisted of two Ordnance QF 6-pounder (57mm) 6 cwt Hotchkiss gun. as main armament and seven .303 Hotchkiss Portative MkI machine guns as secondary armament.

|

| The .303 Hotchkiss Portative tank machine gun |

|

| A diagram of Major Alden's patent: the sponson pivotage system, with a red detail (current design) of the sponson sliding course. |

|

| The right sponson of Mk VIII tank in closing process, showing where sponson pivot (simple red arrows) and the opening between the rear portion of sponson and the side of the tank (double pointed arrow) |

In addition to the two machine guns in the side doors (red-4, in the drawing below), there were five more machine guns, making a total of seven small arms. These five machine guns were all in the superstructure on top of the hull, namely: two in the front arch (red-1), flanking the driver, one on each side, just behind the commander's cupola (red-2) and one machine gun pointing to the rear (red-3). This rear machine gun featured a blind spot in the lower rear region of the tank (black-6) and enemy infantry could take advantage of this vulnerable blind spot. To solve this problem, a triangular bullet deflector plate was attached to later versions of the tank, mostly American versions. The rear superstructure gunner could use this deflector plate to "spray" his bullets into this area behind the tank. This same type of device was later fitted to the American M2 medium tank.

The seven machine guns were fitted on ball mounts. Three of them were installed in large hemispherical housings: one in each of the two side doors of the hull and one at the rear of the fixed turret. These three housings were pivoted at the top and bottom, thus increasing increasing the horizontal traverse of the machine guns allowing them to fire upon targets much closer to the tank.

|

| The lateral machine guns were installed at the side doors, just after the sponsons with the cannons. Here, the right .30 Browning M1919 tank machine gun installed in large hemispherical housing. |

|

| The large hemispherical housing for machine gun in the rear of the fixed turret. |

The two sidewalls stations in the fixed turret (red-2, in the drawing above) were eliminated on American-produced tanks, as their angles of fire were the same as those covered by the door machine guns (red-4).

In addition to these modifications, US-built tanks were armed with the M1919 Browning MG tank machine guns, with the barrel encased in a heavy protective sleeve.

The tank hulls were built by the classic technic of riveting the armor plate to a framework of angle iron and steel channels. The face hardened armor plate varied in thickness from 6mm on the top to 16mm for the fixed turret (casemate) side plates. Unlike earlier British designs, the hull of the Mark VIII was divided by a bulkhead separating the fighting compartment in the front from the engine compartment in the rear. Two sliding doors, one near each side of the tank, permitted movement between the two compartments. Another opening in the center of the bulk-head was closed by a vertical sliding door.

This arrangement was a great improvement in the design and ergonomics of the tanks, as it lessened the noise and heat load borne by the crew, allowed for better breathing in the fighting compartment by eliminating engine exhaust gases, and reduced the danger of fire. A 25.5 cubic meters per minute fan installed in the right front of the engine compartment supplied air for ventilation.

|

| Mk VIII Liberty tank in a period cutaway drawing. Notice the crew in separate engine and transmission compartment |

The British tanks used Ricardo V-12 engines, with 300 Hp of power. US-built tanks were propelled by a 12-cylinder, liquid-cooled, Liberty aircraft engine modified for this application.

|

| British Ricardo 12 cylinder engine - 300 hp Two sets of six standard Ricardo 6 cylinders arranged as a V engine font: IWM pic Q 14581 |

The power of the engines was transmitted through an epicyclic gear box and a chain drive to the track driving wheels (sprockets) at the rear. Petrol was carried in three gasoline tanks, each with a capacity of 300 liters, installed in the rear of the hull isolated from the engine compartment by another bulkhead. The three tanks were pressurized by an engine driven air pump which forced the gasoline into a gravity feed tank directly above the engine. The engines were fitted with an electric started, however, it was not intended to start a cold engine without help from the hand crank. The latter extended through the bulkhead into the fighting compartment.

|

| Mk VIII Liberty tank -sectioned drawing view Notice the transmission (right after the main clutch) and exhaust systems. |

On the pilot tank, the exhaust pipes exit through the rear on each side of the hull. As mentioned previously, this arrangement proved to be unsatisfactory during the test program and it was recommended that the exhaust pipes and mufflers be relocated to the top of the rear hull. This was done on the tanks manufactured in Britain. However, on the American tanks, the upper exhaust pipes were extended without the installation of any mufflers. With that, the yankee tanks were much noisier (see drawing above).

In absolute terms the vehicle was very large: at 3.12 m tall the Mark VIII was the third largest operational tank in history, after the 4,09 m of Char FCM 2C and the 3,90 m of the Fiat 2000. However its weight was only 38.9 tons, fitted for battle as the armour plate was thin with a thickness of 16 mm on the front and sides - a slight improvement over the Mark V but very thin by later standards. The roof and bottom of the hull were protected by only 6 mm thick armour plate, leaving the tank very vulnerable to mortar shells and landmines.

|

| American Mk VIII no. 5 under construction. Notice in the thickness of the plates used. This big tank really had a very thin armor, even for the time. |

The traction system was by tracks, unsprung, supported by 29 lower rollers, attached directly to the vehicle's hull. In the upper part, the tracks ran on rails and only one upper roller was positioned more or less in the middle of the hull, where the track angle changed. Top speed was about 8.0 km per hour on flat terrain.

The track length was 10.41 m but even though the hull width was an impressive nominal 3.76 m, the actual length-width ratio of the tracks was very poor as that width included the sponsons. Combined with wide tracks it proved difficult to turn the tank.

During testing many tracks twisted and broke in a turn and it was decided to use longer, stronger 337 mm links made of hardened cast armour plate, stiffened by webs formed by recesses in the track plate.

A great deal of confusion exists about the number of crew for this tank. Sources cite numbers from 12 to 9 crew members, described as follows: Commander, driver, two gunners and two loaders for the 6 pdrs guns. And two machine gunners in the side stations of the turret, one in the aft station of the turret and two in the doors, besides a mechanic, who sat in the engine compartment. This makes a total of 12 crew members. With the removal of the two stations of the sides of the turret, the Americans reduced the presence of two crew members. And some sources think that the presence of a mechanic was a waste of crew, as one of the machine guns on the doors could have that function. Therefore, the number could vary from 12 to 9 crew members.

|

| Period drawing showing some combat stations on the Mk VIII Liberty tank |

The driver's station was located in the front and middle position of the tank's hull, with the driver sitting on a raised seat, with the control levers at his side and with his head protected by a small rectangular armored cupola, situated directly in front of the fixed tower. There were 3 peepholes (one forward facing and two sideways) for viewing and the front plate of the driver's cupola was hinged to allow direct viewing (and ventilation) when not exposed to enemy fire.

The tank Commander was usually located in the center of the fixed turret, under a small rectangular dome, with 4 vision slots. This rectangular cupola could not rotate, but it was retractable (by means of some screws) and could be withdrawn into the fixed turret in order to reduce overall height for rail travel.

An officer's kit box on the floor of the fighting compartment for the Commander to stand on provided enough height for him to see through the peep holes in the armoured cupola.

The rear gunner manned the rear machine gun crouched over the ammunition lockers, facing aft. On British tanks, this space was shared with the two side machine guns, which must have been quite cramped.

|

| Some combat stations in the Mk VIII tank |

The door gunners were just behind the side access doors, standing, handling the weapons. The hemispherical housings of the machine guns allowed a wide angle of fire for the weapons, which resulted in the elimination of side turret gunners on American tanks, which increased crew effectiveness without sacrificing firepower.

|

| Some combat stations in the Mk VIII tank |

|

| Hatches and doors for crew access |

The tank carried 182 high-explosive shells (HE) 6 pdr. guns, 26 rounds of smoke shells and from 15.000 to 21.000 machine gun rounds.The 6 inch shells were stored in racks installed in the sides and in the lower portion of the sponsons. The projectiles were also stored on shelves flanking the central driver's station and in a large central ammunition closet, located in the middle of the vehicle, next to the floor. Above the cannon shells were stored the projectiles for the machine guns.This cabinet served as a platform for the gunner of the aft machine gun.

|

| Back-to-front view of the driver's station.(British version) Note the two ammo side racks (green arrows), the sponsons movement hinges (red arrows) and the driver's front view slit. |

As we have seen, there were some differences between tanks made in England and those made in the United States. See these details in the photos of American tanks, below:

- The two machine gun positions at the sides of the turret were eliminated (red arrows)

- Use of .30 Browning M1919 machine guns, with their armored barrel covers (green arrows)

- Installation of a semaphore mast, for communication between tanks (dark blue arrow).

|

| American Mk VIII Liberty tank |

- bullet deflector plate installed at rear of tank (orange arrows)

- canvas cover, to reduce water infiltration, in the stored tanks (light blue arrow).

Most of these tanks were used on training exercises and only two modifications are recorded. One such program was in an attempt to improve the Commander's operational visibility, the US Army Artillery Department developed a project (from 1920 to 1925) experimenting with so-called stroboscopic cupolas, such as in the French FCM 2C super-heavy tank. The American stroboscopic cupola had only a single slotted cylinder, being simpler than the French one. Swiveling vertical slots allowed a 360° view, albeit with a reduced light level.

Unfortunately, testing showed that the strobe vision dome was extremely vulnerable to shrapnel from .30 caliber bullets. Later developments attempted to improve the equipment, but on May 4, 1926, the Ordnance Committee concluded that the device was inherently inferior to the periscope and recommended that development cease. The single Mark VIII tank was fitted with a strobe dome for testing, then reverted to the standard pattern.

Another engineering development was the result of avoiding a chronic defect in the Liberty tanks: the leakage of coolant through the engine cooling lines. Many tanks featured cylindrical water tanks on the aft decks to keep coolant levels in conditions to prevent overheating of the engines. To solve this problem once and for all, avoiding these clumsy adaptations, it was planned replace the liquid-cooled Liberty engine (with its sensitive coolant lines) by an air-cooled one.

|

| Mk VIII Liberty tank climbing a ravine. Note the cylindrical water tank adapted on the top deck of the tank (red arrow) and the absence of silencers on the exhaust pipes (blue artrows). |

During 1932, an air-cooled Liberty engine was evaluated in the Mark VIII tank at Aberdeen Proving Ground. Modified by the Heat Controlled Motor Company, the vehicle featured an upgraded air circulation system and the engine had a higher compression ratio of 6:1. This tank was easily identified by the presence of an external fan set, installed on the left side of the hull.

|

| Mk VIII Liberty tank air-cooled engine manned by cadets during training Notice the big side grill on the left rear of the tank. July - 1928 |

Although limited testing did not determine the durability and reliability of the modified engine, the use of air-cooled engines was considered theoretically safer for use in tanks and further development of this principle was recommended.

Operational history

As previously mentioned, only American tanks were officially incorporated into the armored corps of its army and used operationally. The American Liberty tanks equipped a single unit: the 67th Infantry (Tank) Regiment, based in Aberdeen, Maryland.

The curious designation of the unit had its origin in the fact that since 1922 by law all tanks had to be part of the Infantry. Some Liberty tanks were assigned to the 301st Tank Battalion (Heavy), later redesignated the 17th Tank Battalion (Heavy). Throughout most of 1921 and 1922, Major Dwight D. Eisenhower commanded this unit.

|

| American Mk VIII Liberty tank in training. Notice the semaphore pole, the absence of middle MG station and the cilinder in the rear deck (water tank for the engine cooling system.) |

|

| An interesting photo among contemporary vehicles: Size comparison between Ford 3-ton M1918 tankette , 7-ton. M1917 light tank and the Mk VIII Liberty heavy tank USA - 1919. |

|

| A brand new Mk VIII Liberty tank |

|

| American Mk VIII Liberty tanks training at Camp Meade, Maryland - 1922 |

|

| Mk VIII Liberty tanks under training and evaluation Notice the water tank in the rear of the fixed turret |

|

| Mkm VIII Liberty tank in crossing river training, with 67th Infantry Regiment |

|

| Public demonstration of Mk VIII Liberty tanks at Camp Meade, Maryland, in 1925. |

|

| A 7-ton. M1917 light tank climbing in the rear of Mk VIII Liberty tank. The purpose of this maneuver is really unknown.... Camp Meade - 1921 |

By this time, the concept of a heavy, slow, lightly armored large tank was proving to be obsolete and interest had shifted to smaller, lighter, and faster armored vehicles for further development.

In 1932, the now obsolete Mark VIIIs were withdrawn from active military service and stored at the Aberdeen Proving Ground.

|

| Mk VIII Liberty tanks in storage in sheds and under tarps. A melancholy vision for such beautiful machines.... Aberdeen Proving Ground - 1932 |

|

| Mk VIII Liberty tanks in storage Aberdeen Proving Ground - 1932 |

|

| Mk VIII Liberty tanks in storage Aberdeen Proving Ground - 1932 |

In April 1936, the Ordnance Committee recommended that the requirement for a heavy tank be canceled and removed from the Ordnance Book of Standards. This action was passed on May 7 (This measure would later be regretted, with the advent of WWII). The Mark VIIIs remained in storage at Aberdeen until after the outbreak of World War II. In 1940, Canada had a lack of training tanks and were offered the remaining tanks at scrap value, but the Canadians instead opted to purchase M1917 light tanks. The sad end of these machines was scrapping.

Surviving examples:

A Liberty tank survives at Fort Meade in Maryland. The tank was displayed in the Post Museum and was made in 1920 at the Rock Island Arsenal, Illinois. It was assigned to the 301st Tank Battalion (Heavy), later redesignated the 17th Tank Battalion (Heavy). Throughout most of 1921–1922, Major Dwight D. Eisenhower commanded this unit. Today, this tank is displayed in the US Army’s Armor & Cavalry Collection at Ft. Benning.

|

| Mk VIII Liberty tank when it was exposed to the public at the Post Museum - Fort Meade. Vehicle in very good condition, with practically flawless interior, but without the main armament. |

|

| Mk VIII Liberty tank when it was exposed to the public at the Post Museum - Fort Meade Interior view |

|

| The same Mk VIII Liberty tank, now at US Army’s Armor & Cavalry Collection at Ft. Benning, in very good company... |

A second American Liberty tank was at the Aberdeen Proving Ground in Aberdeen, Maryland; it was moved to the U.S. Army Armor and Cavalry Collection at Fort Benning, Georgia in 2014, and was inside until 2021. The interior has extensive damage from water/rust, although plans are in place for structural repairs. This tank was what was modified to use the air-cooled Liberty engine. It still features the large opening on the right side of the shield for the engine compartment fan.

|

| Mk VIII Libery tank (air-cooled engine version) Interior view - mid ship view |

|

| Mk VIII Libery tank (air-cooled engine version) The main characteristic of this vehicle... |

The tank was moved in May 2021, back to its original construction location, at the Rock Island Arsenal in Rock Island, Illinois, with plans to refurbish it and place it on public display at a later date.

|

| Mk VIII Liberty tank (air-cooled), manufactured at Rock Island Arsenal, makes it way home through the streets of Moline, Illinois. The tank will be restored for future viewing. May - 2021 |

|

| Mk VIII Liberty tank (air-cooled) on her transport trailer... |

|

| ...and being unloaded inside the Arsenal. |

The British never allocated their Mark VIIIs to a tank unit. But luckily, one of them, the 12007, survived the scrapping of its sisters. A single vehicle survives at the Bovington Tank Museum, in excellent preservation conditions, proudly sporting the period colors and the white-red-white stripes on the front of the hull.

|

| Mk VIII Liberty tank - built in United Kingdon Bovington Tank Museum The tank is very well maintained and the scale model is simply awesome!! |

|

| British Mk VIII Liberty tank n° 12007 Tank Museum - Bovington. |

Fun Fact:

Although many people say that the tank that appears in the movie from 1989, Indiana Jones and the Last Crusade was a Mk VIII Liberty tank, the truth is the tank appearing in the movie was a replica vehicle made from an excavator, following the hull shape of the Mark VIII but with a rotary turret added.

|

| Still from the movie Indiana Jones and the Last Crusade showing the tank in question |

Specs:

| Mark VIII tank - Liberty / International tank | |

|---|---|

| Place of origin | United Kingdom United States |

| Production history | |

| Designed | 1917 |

| Manufacturer | UK: North British Locomotive Company US: Rock Island Arsenal |

| Produced | 1918–1920 |

| No. built | 125 |

| Specifications | |

| Mass | 38 t - dry weight |

| Length | 10.41 m |

| Width | 3.56 m 2.7 m - sponsons in |

| Height | 3.12 m |

| Crew | 12 or 9 |

| Armor | 16 mm maximum |

Main armament | 2x QF 6 pdr 6 cwt 57mm Hotchkiss guns |

Secondary armament | 7x.303 Hotchkiss Portative Mk I MG or 5x.30 M191 Browning MG |

| Engine | V-12 Liberty (USA) V-12 Ricardo (UK) 300 hp (220 kW) |

| Power/weight | 7.89 hp/tonne (5.79 kW/t) |

| Suspension | unsprung |

Operational range | 80 km |

| Maximum speed | 8.5 km/h governed to 10.0 km/h maximum |

The kit:

This is a commission project and my client, who is a fan of interwar vehicles, sent me this 3D printed kit for assembly. And here we go with another product from Vargas Scale Models. I really like Vargas kits and Luis Vargas is a good friend of mine, but we are here to comment on the kit and its positive and negative details in the most honest way possible. So get to work, Kojak!!!

The kit is the Liberty- International Mk VIII Heavy Tank - 1917 (#R3D- 35070) and here we already have a constructive criticism: the Liberty was built at the end of WWI, that is, in 1918. I don't understand why the date 1917 on the box and on the identification plate of the vehicle.

|

| Kojak in my workbench, with Vargas Models box kit |

|

| What's in the box: few but very detailed pieces. The date 1917 on the vehicle's identification plate is an error: the correct date would be at least 1918...The ideal would be 1919. |

Here, some minor and serious defects: the bending on the Hotchkiss machine guns is due to careless packaging (green arrow) and the printing flaws on the muzzles of the 6 pdr guns. are a quality control error (red and blue arrows): these parts should not have been incorporated into the final sale product.

|

| Bendings on the Hotchkiss machine guns and flaws on the muzzles of the 6 pdr guns |

|

| Here a small graft surgery will be necessary... |

I used a segment of a Plastruct polystyrene tube to make the graft in the most severe case (red arrow, below). In the other cannon, it was just a matter of gluing the fragment (which was still adhered to the part - green arrow) and rectifying it with putty and delicate sanding...

|

| A little Celtic sorcery to correct these defects... |

|

| A positive point: the delicacy and detail of the cooling grids on the upper deck of the tank. Really good!!! |

A precious tip: when you are going to build the cannons on the rotating sponson shields, before sanding these parts, reinforce the bases of the cannon trunions with cyanoacrylate. These pieces are extremely delicate and brittle, being "adhered" to the shields only in small portions.

|

| The same treatment was performed on the other side... Be careful not to block the movement of the 6 pdr. gun |

Here, I'm going to change the order of construction: I'm going to reinforce this whole joint, using small pieces of plasticard (green arrows, below...), and then I'm going to insert the gun+ shield through the sponsons openings. It's a little more work, but I manage to reinforce these trunions, guaranteeing the movement of the main weapons.

|

| The most reinforced trunions, by Crom!! |

|

| Crom likes Strength and Power!!! |

And here, the insertion of the shield into the sponson: the lower part fits easily, but the gun's upper semi-circular armor gets in the way. Just push that "petal" down with a thin instrument (green arrows) and at the same time, push the petal inwards (red arrow), gently. The shield just fits like a glove. Delicacy and patience of a Tibetan monk...

|

| Squeeze and push gently... |

|

| ...and the cannon rotor fits like a glove!!! |

|

| Inside view of this detail: you first fit the lower portion (1) and then compress and insert the upper portion (2). |

|

| The two guns of 6 pdr. with his movements preserved... Good job, Grasshopper!!! |

|

| After these details, let's glue the two suspension sets to the tank hull. An imposing machine!!! |

|

| Squaring is essential... Be careful not to destroy your tank's aesthetics with a construction error... |

|

| The kit is really beautiful!!! |

|

| Rear view |

|

| The detail of the exhaust pipes with mufflers, typically British. And the absence of the deflector plate for the rear machine gun (these Yankees are crazy...) |

|

| The detailing of the kit is very good. I really liked this girl, Vargas!!! |

|

| Primer time!! Left side |

|

| Right side |

As I said, this project is a commission and I know my client loves European material. So, no red-neck tanks...let's make one of the old Albion ones, for Saint George's sake!!!

I loved this photo, so here's our girl: Mk VIII Liberty tank CITY OF BRADFORD VII.. in field tests at Bovington in Dorset, England, in early 1919.

|

| British Mk VIII Liberty heavy tank CITY OF BRADFORD VII in trials - Bovington in Dorset, England - early 1919. |

|

| Panzerserra's color & markings guide |

With the historical identification solved, let's go to the painting...

|

| Base color. left view |

|

| Base color. right view |

|

| Some tonal variations of the base color... old-school style painting, to match the girl's elegance... left view |

|

| Right view |

|

| Rear view |

|

| Starting painting the tracks... left view |

|

| Painting the tracks... right view |

|

| The glorious white-red-white combat bands. |

|

| How beautiful is it getting!!! |

For the marking of the girl's name, based on the study of real photography, I made a plate with plastic and made a decal with the name of the city on my laser printer, using the Panzerserra technique of two layers of transparent decals: In the first layer, I painted the letters with a thin brush and white paint and, after the paint dried, I applied the second layer of transparent decal, with the black edges of the letters hiding the paint defects. I really liked the end result...

|

| City of Bradford VII - right side |

|

| City of Bradford VII - left side |

|

| The nameplate, which was glued to the hull after the decals were applied... |

|

| Americans, forgive me, but this little big English girl is getting really pretty!!! |

|

| Starting the weathering... |

|

| Front view |

|

| Left view |

|

| Rear view: notice the exhausts with mufflers and the "clean" tail, without the bullet deflector |

And while I was detailing the weathering effects, I realized one thing: the kit does not feature the side vision slits on the driver's armoured dome!!! In the kit, there is only the front vision slit, but the driver needed the two side ones. And this detail is evident in the photos of the tank and in the blueprints. See the images below:

|

| The side vision slits in thr driver's cupola |

But ihis detail is missing in the kit. And the worst thing is that I only realized this flaw now, after the kit was almost finished... But better late than never!!!

|

| Calm down Boromir!!! Let's settle this... |

|

| The solution is simple: make the vision slits armours with very thin plasticard (0.3 mm thick) |

|

| With the shields of the vision slits made in plasticard, now it's just a matter of soldering the pieces with superglue |

|

| Driver's left vision slit in position... Yeah!! I'm happy and satisfied, now!!! |

|

| Driver's right vision slit in position... |

|

| Driver's left vision slit, after painting... Tommy is happy, indeed!!! |

|

| The driver now has a better view of the vehicle's operating situation... |

|

| Right view... Hurrah!! |

And while Boromir was upset about the absence of the driver's vision slit, he remains dismayed by the presence of this armor plate in the kit that is non-existent on real vehicles. Okay, Vargas... a little more careful, my friend.

|

| Where the hell did that armor plate come from??? |

But let's go ahead... Let's paint and install the Hotchkiss machine guns on the ball mounts. Warped Hotchkiss were aligned by dipping the machine gun barrels in hot water and straightening the alignment of the pieces with fingers...

|

| A good trick is to glue the Hotchkiss on a piece of plastic to make painting easier... |

|

| Close view |

And after more weathering details, we can call this girl ready for work. Meet CITY OF BRADFORD VII, a heavy Mk VIII Liberty tank, built by the British at North British Locomotive Company, in performance tests around Bovington in Dorset, in early 1919.

|

| Mk VIII Liberty heavy tank CITY OF BRADFORD VII Bovington in Dorset, England - early 1919. |

|

| Mk VIII Liberty heavy tank CITY OF BRADFORD VII left front view |

|

| Mk VIII Liberty heavy tank CITY OF BRADFORD VII left front top view |

|

| Mk VIII Liberty heavy tank CITY OF BRADFORD VII left view |

|

| Mk VIII Liberty heavy tank CITY OF BRADFORD VII left front view |

|

| Mk VIII Liberty heavy tank CITY OF BRADFORD VII left top view |

|

| Mk VIII Liberty heavy tank CITY OF BRADFORD VII left rear view |

|

| Mk VIII Liberty heavy tank CITY OF BRADFORD VII right rear view |

|

| Mk VIII Liberty heavy tank CITY OF BRADFORD VII right view |

|

| Mk VIII Liberty heavy tank CITY OF BRADFORD VII with Kojak |

|

| Mk VIII Liberty heavy tank CITY OF BRADFORD VII right front view |

|

| Kojak is feeling powerful today... |

|

| In a photo from the "Improbable Encounters" series, the Mk VIII Liberty tank together with a M4A3E2 (75) Jumbo assault tank, for size comparison purposes |

|

| Mk VIII Liberty heavy tank CITY OF BRADFORD VII Bovington in Dorset, England - early 1919. |

Thank you for your visit!!!

%20march%201919%20USA%20with%20.303%20mg%20mounts.jpg)